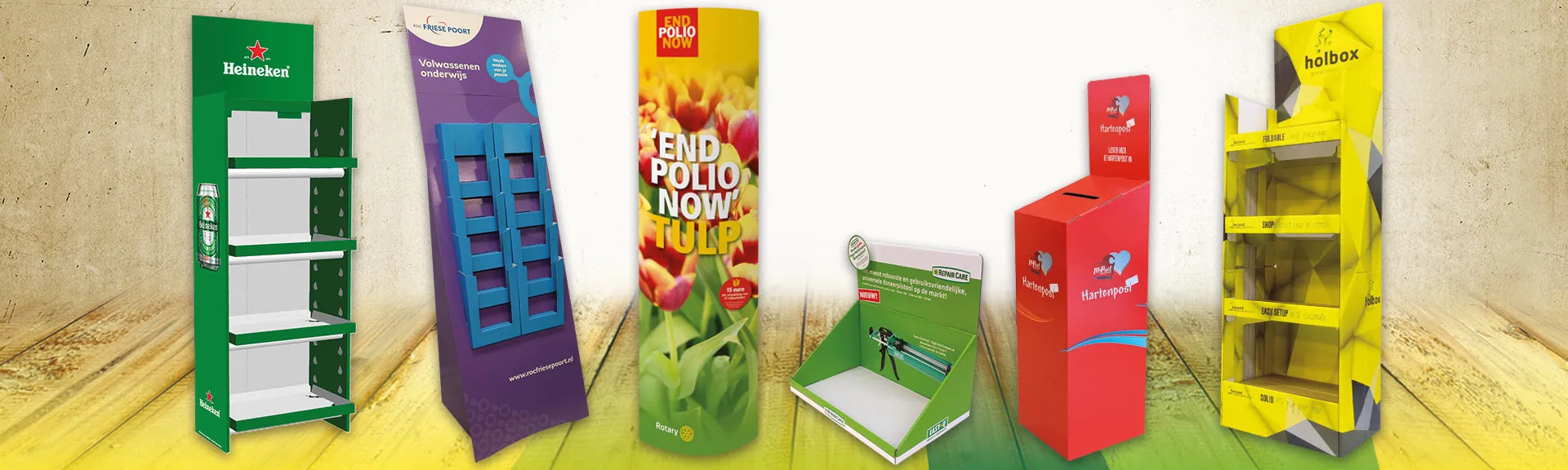

Overwhelmed by display options? The wrong choice can cost you sales and damage your brand. I'll help you find the perfect cardboard display style for your product.

The best cardboard display style depends on your product's size, weight, and where it will be placed. For lightweight items, counter displays are great. For heavier products or large quantities, floor displays like FSDUs or pallet displays are better. The key is matching the display to the product's needs.

Choosing the right style is just the start. The material you use is just as critical. The type of cardboard affects everything from how long the display lasts to how good your products look. In my 16 years, I've seen how the right material makes or breaks a campaign. It’s the foundation of every great display. So, let's look closer at what goes into making a display that not only looks good but also stands strong.

What is the best type of cardboard?

Afraid your display will collapse? A weak cardboard choice can ruin your campaign and damage products. I'll show you how to pick the right type for reliability and success.

There isn't one "best" type of cardboard. The right choice depends on your project. Corrugated cardboard is excellent for strength and is used in most displays. For high-quality graphics, CCNB1 (Clay Coated News Back) is often laminated onto the corrugated board. It's about balancing strength and print quality.

When my clients ask for the "best" cardboard, I tell them we need to define what "best" means for their project. Is it best for budget, best for graphics, or best for holding heavy items? In my experience, the greatest successes come from smart combinations. We start with a corrugated board for the core structure. The magic is in the fluting, the wavy layer sandwiched between paper liners.

Balancing Cost and Quality

A common choice is B-flute2. It offers good strength without being too thick, which keeps the printing surface relatively smooth. For smaller, lighter displays, an E-flute3 is even better because it's thinner and provides an excellent surface for high-resolution graphics. However, trying to save a few cents by using E-flute3 for a heavy product is a mistake I've seen happen. It might look great at first, but it won't last.

Material Combinations for Success

The real professional approach is lamination4. We take a strong corrugated sheet, like B-flute2, and laminate a high-quality printable paper on top, like a 250gsm CCNB1. This gives you the best of both worlds: a strong, durable structure and a beautiful, smooth surface for your branding. This combination is the secret to most of the high-end displays you see in stores.

| Feature | Best For | Common Material |

|---|---|---|

| Graphics | High-end printing, smooth finish | E-flute3, or Laminated CCNB1 |

| Strength | Holding heavy products | B-flute2, C-flute5, or Double-Wall |

| Budget | Cost-effective promotions | B-flute2 with direct printing |

What are cardboard displays called?

Confused by all the industry jargon for displays? Using the wrong name can cause major communication gaps. Let's clear up the terminology so you can order with confidence.

Cardboard displays are known by many names. The general term is POP (Point of Purchase) or POS (Point of Sale) displays. More specific names include FSDU (Free Standing Display Unit), counter displays6, dump bins7, and pallet displays8. The name describes its location or function.

Knowing the right name is crucial. It helps you, the designer, and me, the producer, speak the same language. I remember a client years ago asking for a "big cardboard box for the floor." We spent a lot of time figuring out what they needed. It turned out they wanted a full pallet display for a promotion in a big-box store. Using the right term from the start would have saved us days of back-and-forth communication. Clear language makes the entire process faster and more accurate.

Key Display Terminology

To help you communicate clearly, let's break down the most common terms. Each type of display has a specific purpose and is designed for a particular retail environment. Understanding them will help you align your design with the client's sales strategy.

From Small Counters to Large Pallets

- Counter Display Unit (CDU9): Small, sits on a checkout counter or shelf. Perfect for impulse buys of small items like candy, cosmetics, or batteries.

- Free Standing Display Unit (FSDU): A standalone floor display. This is the most versatile type, often used for new product launches or promotions. They can have shelves, hooks, or a mix of both.

- Dump Bin: A large open bin, great for discounted items or products without primary packaging. It encourages shoppers to "rummage" and find a deal.

- Pallet Display: A large display that ships on a pallet and is placed directly in the aisle of a large store. Ideal for high-volume, fast-moving products.

| Display Name | Acronym | Common Use Case |

|---|---|---|

| Counter Display | CDU9 | Impulse buys at checkout |

| Free Standing Display | FSDU | New product launches in aisles |

| Dump Bin | N/A | Discounted or loose items |

| Pallet Display | N/A | High-volume sales in club stores |

What type of cardboard is used for packaging?

Unsure about the difference between display and packaging materials10? A mistake here can lead to damaged products. I'll explain the key cardboard types used for safe shipping.

For packaging, corrugated cardboard11 is king due to its strength and protective qualities. The specific type, like single-wall or double-wall, depends on the product's weight and fragility. C-flute5 is a common all-purpose choice for shipping boxes, offering a good balance of cushioning and strength.

The purpose of packaging cardboard is different from display cardboard. While a display needs to attract customers, packaging needs to protect the product on its journey. The focus shifts from visual appeal to pure function and durability. The materials we use reflect this. For shipping boxes, strength is everything. The box might get dropped, stacked under heavy loads, or exposed to moisture. It has to survive.

Protection First

The primary material for shipping boxes is standard corrugated fiberboard. Unlike the specialized boards for displays, packaging board is all about durability. Kraft paper, made from virgin wood pulp, is often used for the liners because its long fibers give it superior tear and burst strength. Recycled paper liners, or test liners, are also used, but they are generally not as strong. The choice depends on how much protection the product needs.

The Role of Flutes in Packaging

The flute type is also critical. While an E-flute3 is for displays, a C-flute5 is the workhorse of packaging. It's thicker than B-flute2 and offers better cushioning and stacking strength, making it a great all-around choice for shipping boxes. For very heavy or fragile items, we move to double-wall board, which combines two layers of flutes, like a B and a C flute together (BC flute), for maximum protection. This is the kind of material used for shipping appliances or heavy parts.

A great project often combines both worlds. We can design shelf-ready packaging12 (SRP) that acts as a tough shipping box and then easily converts into a display on the shelf. This is smart design that saves time for retailers.

Which type of cardboard is best for strength?

Need to display heavy items? A weak display is a safety hazard and a huge liability. Here’s how to choose cardboard that guarantees strength and peace of mind.

For maximum strength, double-wall or even triple-wall corrugated cardboard11 is the best choice. A combination like a BC flute, which bonds a B-flute2 and a C-flute5 layer together, offers excellent rigidity and compression strength. The type of paper liner, like Kraft paper, also adds significant strength.

[^11]](https://leader-display.com/wp-content/uploads/2025/07/Strong-Double-Wall-Cardboard.jpg)

When a client needs a display for heavy products like beverage cans, glass jars, or bags of pet food, my main focus is safety and stability. The material is the starting point, but true strength comes from a combination of the right material and smart structural design13. You can't have one without the other. Choosing the strongest board is useless if the display itself is poorly designed.

It's All in the Flutes and Liners

For heavy-duty applications, we always start with double-wall corrugated board. A BC flute is my go-to choice. The C-flute5 provides excellent vertical strength for stacking, while the B-flute2 adds rigidity and impact resistance. The paper is just as important. We use heavy-duty Kraft liners14 because their strong virgin fibers resist tearing and puncturing. The weight of the paper, measured in GSM (grams per square meter), also matters. A heavier liner means a stronger board.

Structural Design is Key

Material alone isn't enough. We once designed a display for wine bottles, a very demanding product. We used a strong BC flute board, but the real secret was the internal structure. We engineered a separate, hidden support grid inside the display. Each shelf locked into this internal frame, transferring the weight down to the base. The outer shell was just for graphics and branding. The internal structure did all the heavy lifting. This is how you build a cardboard display that can safely hold significant weight. It’s this combination of material science and engineering that creates a truly strong and reliable display.

Conclusion

Choosing the right display involves matching the style to your product and the cardboard to your needs. Focus on strength, function, and goals for a successful campaign.

-

Learn about Clay Coated News Back (CCNB) and its role in enhancing print quality for displays. ↩ ↩ ↩

-

Find out why B-flute is a popular choice for strength and smooth printing surfaces in displays. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the advantages of E-flute for high-resolution graphics in smaller displays. ↩ ↩ ↩ ↩

-

Learn how lamination can enhance the durability and appearance of cardboard displays. ↩

-

Discover why C-flute is commonly used for shipping boxes due to its cushioning and strength. ↩ ↩ ↩ ↩ ↩

-

Learn about counter displays and how they can effectively showcase lightweight items at checkout. ↩

-

Find out how dump bins can encourage shoppers to explore discounted items and increase sales. ↩

-

Understand the benefits of pallet displays for high-volume sales in retail environments. ↩

-

Understand the role of Counter Display Units (CDUs) in promoting impulse buys at checkout. ↩ ↩

-

Learn about the different types of packaging materials that ensure product safety during shipping. ↩

-

Explore the properties of corrugated cardboard that make it ideal for strength and durability in displays. ↩ ↩

-

Discover how shelf-ready packaging combines shipping efficiency with display functionality. ↩

-

Learn how effective structural design can enhance the strength and stability of cardboard displays. ↩

-

Understand the importance of heavy-duty Kraft liners in enhancing the strength of cardboard displays. ↩

2 Responses