Your products look great, but will the display work? Customers worry about cost, stability, and looks. It's a common problem I've seen for 16 years.

Customers often ask about display names, stability, and materials. The best solutions use strong corrugated fiberboard, smart structural design for support, and clear branding to attract shoppers and boost your sales.

Over my 16 years in this business, I've heard every question you can imagine. It is very satisfying to answer their questions. Let's break down some of the most common ones our clients bring to me. Answering these will help you design a display that truly works in the real world.

What are cardboard displays called?

You have a great display idea, but what do you call it? Using the wrong name leads to confusion and wasted time with suppliers. You need correct terminology.

Cardboard displays have many names like Point of Purchase (POP) displays1, FSDUs (Free Standing Display Units2), counter displays, or dump bins. The name usually describes where and how it's used.

Knowing the right name for a display is the first step. It helps you communicate clearly with designers and manufacturers. When a client comes to me, we first talk about their goal. This helps us pick the right type of display. For example, a "Point of Purchase" (POP) display is a broad term for any display where a customer might buy something. It's about catching their eye. A "Free Standing Display Unit," or FSDU, is more specific. It's a standalone display that you can walk around. We use these in wide aisles to create a big impact. I always tell my team that understanding these terms isn't just about vocabulary. It's about understanding the client's strategy and the retail environment.

Common Display Terminology

Here is a simple table to help you understand the most common terms.

| Term | Full Name | Common Use |

|---|---|---|

| POP Display | Point of Purchase Display | General term for any retail display. |

| POS Display | Point of Sale Display | Display located right at the checkout counter. |

| FSDU | Free Standing Display Unit | A standalone floor display. |

| Counter Display | Counter Top Display Unit (CTU) | A small display that sits on a counter. |

| Dump Bin | - | A large bin for small, loose, or discounted items. |

| Pallet Display | - | A large display shipped on a pallet for bulk sales. |

What are cardboard display boxes?

Your product packaging looks good but gets hidden on the shelf. Retail staff have to unpack every single item. There has to be a better way for display.

These are often called Shelf-Ready Packaging3 (SRP) or Retail-Ready Packaging4 (RRP). They are smart boxes that ship your product and then easily convert into an organized display on the shelf.

A few years ago, a client with a new snack bar came to us. Their bars were just getting lost on the shelf. We suggested switching to Shelf-Ready Packaging. The change was amazing. Instead of store workers stocking individual bars, they just placed the whole box on the shelf and tore off the front panel. This saved the store time and made my client’s products look neat and organized. Sales went up by nearly 20% in the first few months. SRP is a win-win solution. It makes life easier for the retailer and makes the brand look more professional. For a product designer, the key is the perforated tear-away section. It must be strong enough to survive shipping but simple enough for any store employee to open easily. We always create several prototypes to test this feature before we go into full production.

Key Benefits of SRP

- For Retailers: It’s faster to restock shelves. It reduces packaging waste in the aisle and keeps shelves looking tidy.

- For Brands: It guarantees your product is displayed correctly. It creates a mini-brand-billboard right on the shelf, improving visibility against competitors.

How to make a cardboard display stand up?

You've designed a beautiful display, but will it fall over? An unstable stand is a huge risk for your brand and your products. Stability is not an option.

To make a display stand up, you need a strong foundation. This means a wide base, internal supports5 like shelves or grids, and using the right grade of corrugated cardboard for the weight.

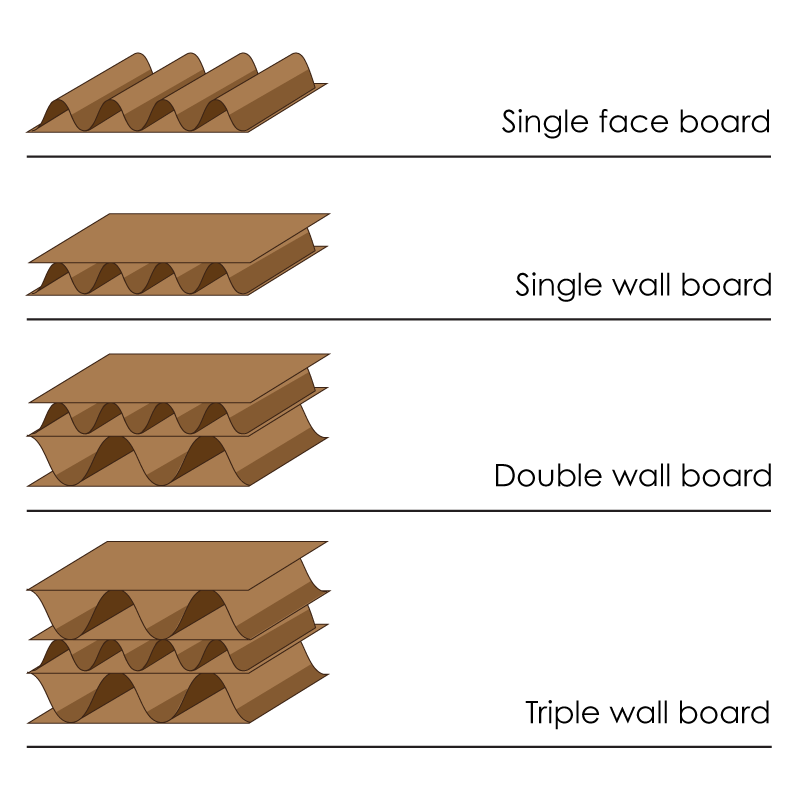

I always tell my designers to think like architects. A cardboard display is a small building. It needs a solid foundation and a strong internal frame. The secret is in the structure you can't see. We use internal latticework, support shelves, and back panels to distribute the weight of the products evenly. The choice of material is also critical. A display for heavy items like bottles of water needs a much stronger grade of cardboard than one for light items like bags of chips. We often use double-wall corrugated board6 for heavy-duty stands. One of the most important steps in my company's process is prototype testing7. We build a full-scale model of the display and load it with weights that are heavier than the actual products it will hold. We check for any weak points or leaning. This ensures the final display is safe and reliable in a busy store.

Choosing the Right Material

The strength of your display depends on the flute of the corrugated board.

| Flute Type | Thickness | Common Use |

|---|---|---|

| E-Flute8 | Very Thin (~1.5 mm) | Small boxes, high-quality printing surface. |

| B-Flute9 | Thin (~3 mm) | Good balance of strength and printability. Great for SRP. |

| C-Flute10 | Standard (~4 mm) | The most common flute for shipping boxes and basic displays. |

| BC-Flute | Thick (~7 mm) | Double-wall board for heavy products and strong floor displays. |

What is cardboard called in America?

You're talking to a US supplier, but they seem confused. Using "cardboard" might not be specific enough. Clear communication is key to getting what you need.

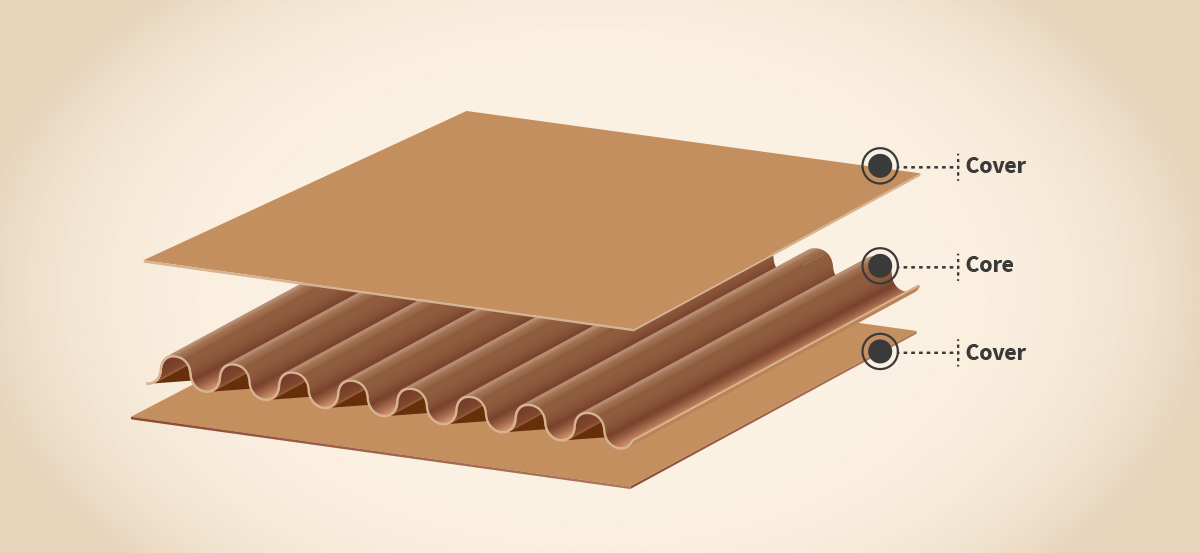

In American industry, the material for displays is called "corrugated fiberboard11" or just "corrugated." "Cardboard" is a general term, while "paperboard12" refers to thinner material for small boxes, like a cereal box.

This might seem like a small detail, but it can cause big confusion. I remember an early call with a U.S. partner where I kept saying 'cardboard' for a heavy-duty floor display. They finally asked, 'Do you mean BC-flute corrugated?' It was a learning moment for me. In the U.S. market, professionals use specific terms. "Corrugated" refers to the material with the wavy layer, called the flute, sandwiched between two flat linerboards. This structure is what gives it strength. "Paperboard" or "card stock" is a single, flat layer of paper, like what a greeting card is made from. Using the right term like "corrugated" shows you understand the industry. It helps your supplier immediately know you are talking about structural material for displays or shipping, not just a simple folding carton. This clarity saves time and prevents costly mistakes.

Quick Guide to American Terms

| Term | What It Means | Example |

|---|---|---|

| Corrugated | A structural material with a wavy internal flute. | Shipping boxes, floor displays. |

| Paperboard | A thick, single-ply paper sheet. Also called card stock. | Cereal boxes, small product cartons. |

| Chipboard13 | Non-corrugated board made from recycled paper pulp. | Backing for notepads, internal packaging. |

Conclusion

Understanding these key terms and design principles is the first step. It helps you talk to suppliers and create displays that are stable, effective, and boost your sales.

-

Explore this link to understand how POP displays can enhance customer engagement and boost sales. ↩

-

Learn about FSDUs and how they can create impactful retail displays that attract customers. ↩

-

Discover how SRP can streamline restocking and improve product visibility on shelves. ↩

-

Find out how RRP can enhance your product's presentation and sales in retail environments. ↩

-

Understand the importance of internal supports for stability and durability in display design. ↩

-

Learn why double-wall corrugated board is essential for heavy-duty displays and their benefits. ↩

-

Explore the significance of prototype testing to ensure the reliability of your display designs. ↩

-

Discover the characteristics of E-Flute and its applications in high-quality packaging. ↩

-

Learn about B-Flute's balance of strength and printability for effective retail displays. ↩

-

Understand the standard uses of C-Flute in shipping boxes and basic displays. ↩

-

Explore the structure and strength of corrugated fiberboard for effective display solutions. ↩

-

Learn about paperboard's applications and how it differs from corrugated materials. ↩

-

Discover the applications of chipboard in packaging and its benefits for various products. ↩