Struggling to make your product pop in a crowded store? The wrong display can make your product invisible, costing you sales. Let's explore the types that actually work.

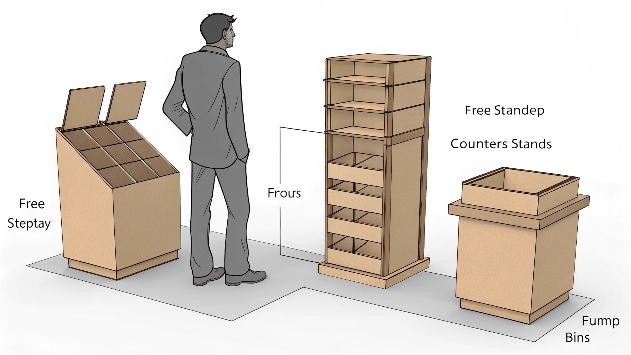

Retail cardboard displays include [countertop displays (PDQs)]1 for impulse buys, [floor displays]2 for high visibility, [pallet displays]3 for bulk items, and [endcap displays]4 for prime aisle placement. Each type serves a specific purpose to maximize product exposure and drive sales in a retail environment.

I've seen firsthand how the right display can transform a product's success. But choosing correctly means going beyond just the basic categories. We need to understand what these displays are called, what they're made of, and how they're produced. This knowledge is key to making a choice that truly benefits your brand and your budget. Let's dive into the specifics to give you a clear advantage.

What are the different types of retail displays?

Feeling lost in the world of retail displays? Choosing without a clear strategy means missing out on prime opportunities. Let's look at the key types to maximize your impact.

Retail displays range from simple countertop units (PDQs) and freestanding [floor displays]2 (FSDUs) to large [pallet displays]3 for bulk sales and high-traffic [endcap displays]4. Other types include [dump bins]5 for promotions and [power wings (sidekicks)]6 that attach to shelving, each designed for a specific strategic placement.

In my 16 years in this business, I've learned that each display type has a specific job. You wouldn't use a massive pallet display for a small, high-value item at the checkout counter. That's where a countertop display, or a PDQ, shines. It encourages last-minute impulse buys. On the other hand, a freestanding floor display (FSDU) is your main workhorse. It stands alone in an aisle, grabbing attention from all sides. Endcaps are the premium real estate at the end of aisles, perfect for new launches or big promotions. And for moving large volumes of product, nothing beats a pallet display that ships pre-loaded and ready to sell. I always advise my clients to match the display type to their sales goal. Here’s a simple breakdown to help you choose:

| Display Type | Common Name(s) | Primary Goal | Best Retail Location |

|---|---|---|---|

| Countertop Display | PDQ (Product Display Quickly), POP | Impulse Buys | Checkout Counters, Deli Counters |

| Floor Display | [FSDU (Free-Standing Display Unit)]7 | High Visibility, Brand Story | Main Aisles, Open Spaces |

| Endcap Display | Gondola End Display | High-Traffic Promotions | End of Aisles |

| Pallet Display | Shipper Display | Bulk Sales, High Volume | Main Aisles, "Action Alley" |

| Dump Bin | --- | Clearance, Promotions | Front of Store, Wide Aisles |

| Power Wing | Sidekick, Gravity Feed | Cross-Selling | Attached to Endcaps/Shelving |

What are cardboard displays called?

Do acronyms like POP, POS, and FSDU make your head spin? It’s frustrating when industry jargon gets in the way. Let's clear up what these terms actually mean.

Cardboard displays are often called [POP (Point of Purchase) displays]8 because they're where a sale happens. Specific types have names like [FSDU (Free-Standing Display Unit)]7, PDQ (Product Display Quickly) for easy-to-stock countertop units, or simply countertop displays, floor stands, and [dump bins]5.

The terms can be tricky, but the most common one you'll hear is POP, or Point of Purchase. This refers to any display where the customer makes a buying decision. Point of Sale (POS) is different—that's the actual transaction spot, like the cash register. I once had a client who kept mixing them up, which caused some early confusion in the design phase. We quickly sorted it out, but it taught me to always clarify terms upfront. Breaking down the names helps:

- [FSDU (Free-Standing Display Unit)]7: This is any display that stands on its own on the floor. It's a broad term.

- PDQ (Product Display Quickly): This usually refers to a smaller display, often for countertops, that comes pre-filled and is easy for store staff to set up. The name says it all—it’s about speed and efficiency. This is where we focus a lot of our innovation at Lddisplay. A complex display that takes 30 minutes for a store employee to build is a hidden cost. We've developed designs that are not just "quick" but can be assembled in literally two seconds. This saves massive amounts of time and labor costs for retailers, a huge selling point for any brand.

What are the different types of cardboard?

Do you think all cardboard is created equal? Choosing the wrong type can mean your beautiful display sags or fails, damaging your product. Let's learn the differences for a sturdy result.

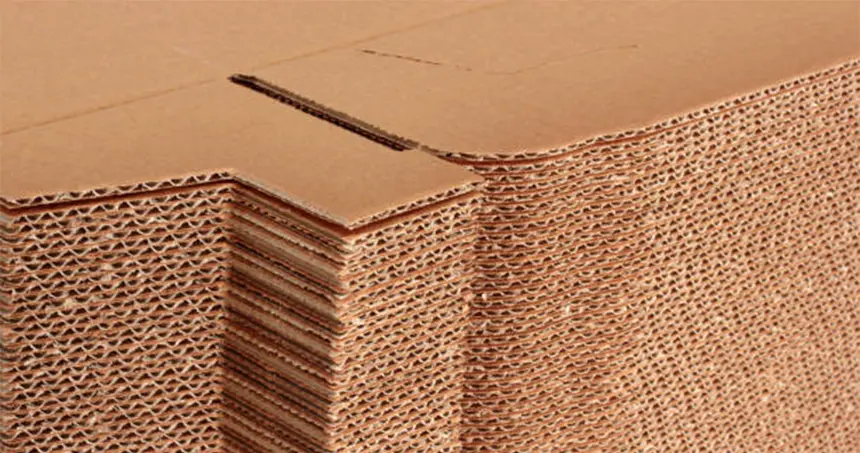

The most common type for displays is [corrugated cardboard]9. It's defined by its [fluting (the wavy layer)]10 and liners. Flute types like B, C, and E offer different thicknesses and strength. For premium looks, we might use SBS board or other paperboards for specific applications.

The term 'cardboard' is a bit general. In the display world, we almost always mean corrugated fiberboard. This isn't just a thick piece of paper; it’s an engineered material. It has three layers: an inside liner, an outside liner, and the "flute" sandwiched between them. The flute is that wavy, zig-zag layer, and it’s what gives the board its strength and rigidity. The size of these waves, or flutes, makes a huge difference.

| Flute Type | Thickness | Characteristics | Common Use |

|---|---|---|---|

| C-Flute | ~4 mm | Good all-around strength. | Shipping boxes, basic [floor displays]2. |

| [B-Flute]11 | ~3 mm | Good strength, better print surface than C. | Most common for POP displays. |

| [E-Flute]12 | ~1.5 mm | Excellent print surface, less durable. | Smaller boxes, countertop displays. |

| [BC-Flute]13 | ~7 mm | Double-wall, very strong. | Heavy-duty [floor displays]2, [pallet displays]3. |

Choosing the right flute is a balancing act. For a heavy-duty pallet display, we’d use a strong double-wall like BC-flute. But for a sleek countertop display that needs to show off high-quality graphics, a thinner E-flute is perfect because its smooth surface allows for crisp printing. This is also where our advanced [color management system]14 becomes critical. We ensure that no matter the flute type, the printed colors perfectly match your brand's colors, creating a seamless and professional look that attracts customers.

What are the different types of cardboard cutting?

How do flat sheets of cardboard become intricate, custom-shaped displays? The cutting method impacts everything from cost to speed. Let's look at how it's done professionally.

The two main methods are [die-cutting]15 and [digital cutting]16. Die-cutting uses a custom steel-rule die for high-volume production, making it cost-effective for large runs. Digital cutting uses a computer-guided blade, which is ideal for prototyping and small, custom orders without tooling costs.

Getting the cut right is fundamental to a successful display. It all comes down to two main technologies: [die-cutting]15 and [digital cutting]16.

- Die-Cutting: Think of this like a giant, industrial cookie cutter. We create a custom tool, called a die, which is a wooden board with steel rules bent into the shape of the display parts. A press then stamps this die onto the cardboard sheet, cutting and creasing it perfectly every time. It’s incredibly fast and cost-effective for large production runs.

- Digital Cutting: This method is more modern. It uses a computer-controlled machine with a blade that follows a digital file to cut the shape. There's no physical die, so it’s perfect for creating one-off prototypes or small orders. It gives us amazing flexibility.

The precision of the cut is crucial for the final step: shipping. A well-cut display assembles perfectly, making it stronger. This is vital when we ship orders overseas. To ensure they arrive safely, we perform rigorous waterproof testing and advise on the best packaging, like palletizing for protection. We even design custom [3D shipping protection cards]17 inside the cartons to protect the display during transit. These steps guarantee a successful global delivery.

Conclusion

Choosing the right cardboard display involves understanding its type, material, and production. This knowledge ensures you select an effective, durable, and eye-catching solution that boosts your retail success.

-

Learn how countertop displays (PDQs) can boost last-minute sales and why they're a strategic choice for checkout areas. ↩

-

Discover why floor displays are essential for grabbing shopper attention and increasing brand exposure in busy aisles. ↩ ↩ ↩ ↩

-

Understand how pallet displays streamline bulk product sales and maximize efficiency in high-traffic store areas. ↩ ↩ ↩

-

Find out how endcap displays can drive promotions and new product launches by leveraging high-traffic aisle ends. ↩ ↩

-

Explore how dump bins can help move excess inventory and attract attention to promotional items in stores. ↩ ↩

-

See how power wings can increase sales by attaching to shelving and promoting complementary products. ↩

-

Learn why FSDUs are versatile, attention-grabbing displays that can be placed anywhere in a store for maximum impact. ↩ ↩ ↩

-

Understand the role of POP displays in encouraging impulse purchases and increasing overall sales. ↩

-

Discover the benefits of corrugated cardboard, including strength and versatility, for creating effective retail displays. ↩

-

Learn how the type of fluting impacts the structural integrity and performance of your cardboard displays. ↩

-

Find out why B-Flute is commonly used for POP displays and how it balances strength with print quality. ↩

-

See why E-Flute is ideal for high-quality graphics and smaller displays that require a smooth print surface. ↩

-

Understand the advantages of double-wall BC-Flute for supporting heavy products and ensuring display durability. ↩

-

Discover how advanced color management ensures your brand colors are consistent and eye-catching on any display. ↩

-

Explore the die-cutting process and why it's cost-effective for large-scale retail display manufacturing. ↩ ↩

-

Learn how digital cutting enables flexible, precise, and low-volume production without expensive tooling. ↩ ↩

-

Find out how custom 3D protection cards prevent damage and ensure your displays arrive in perfect condition worldwide. ↩

3 Responses