Struggling to visualize how a simple idea becomes a finished display? The path from concept to a tangible, store-ready unit can seem complicated, but it doesn't have to be.

The design and manufacturing of a cardboard display involve several core stages. It starts with creative and structural design, moves to digital prototyping, then printing and precise die-cutting. Finally, the pieces are glued, assembled, and flat-packed for efficient shipping to their destination.

In my 16 years in this industry, I’ve guided countless clients through this journey. It might look like a long list of steps, but it’s a streamlined process my team and I have perfected. We turn creative visions into functional, eye-catching displays every single day. Let's walk through each part of the process so you understand exactly how your display comes to life. It’s a fascinating mix of creativity and engineering.

How is cardboard manufactured?

Ever wonder what gives a cardboard display1 its strength? Using a material that isn't up to the job can lead to sagging shelves and a poor brand image.

Cardboard, or more accurately paperboard, is made from paper pulp2 derived from wood fibers or recycled paper. This pulp is pressed, dried, and flattened into sheets. For displays requiring more strength, we laminate3 multiple layers together to create a rigid and durable material.

The journey from raw material to a printable sheet is critical for the final display's success. I’ve seen projects fail because the initial material choice was wrong. It’s not just about thickness; it’s about the very composition of the board.

From Raw Material to Rigid Board

The process starts with creating pulp. This can come from two sources: virgin fibers4 from wood chips or recycled fibers5 from used paper products. We often use a mix to balance strength, printability, and sustainability. The pulp is then mixed with water to create a slurry, which is spread onto large screens to drain the water and form a matted sheet of fibers.

Next, these sheets pass through large, heated rollers that press out more water and compact the fibers into a dense, smooth paperboard. This calendering process6 is key to creating a surface that will accept ink beautifully. I remember one project for a luxury cosmetics brand where the print quality had to be flawless. We selected a board with a high-quality coating applied during this stage, which made the colors pop and gave it a premium feel. It’s these small details in manufacturing that make a huge difference.

| Fiber Source | Key Characteristics | Best Use Case for Displays |

|---|---|---|

| Virgin Fibers | Strong, bright white, smooth surface | High-end graphics, heavy products |

| Recycled Fibers | Eco-friendly, cost-effective, good bulk | General purpose, 'green' branding |

What are cardboard display1s called?

Do you feel lost trying to describe the display you need? Using the wrong industry term can cause confusion and slow down your project, leading to incorrect quotes and prototypes.

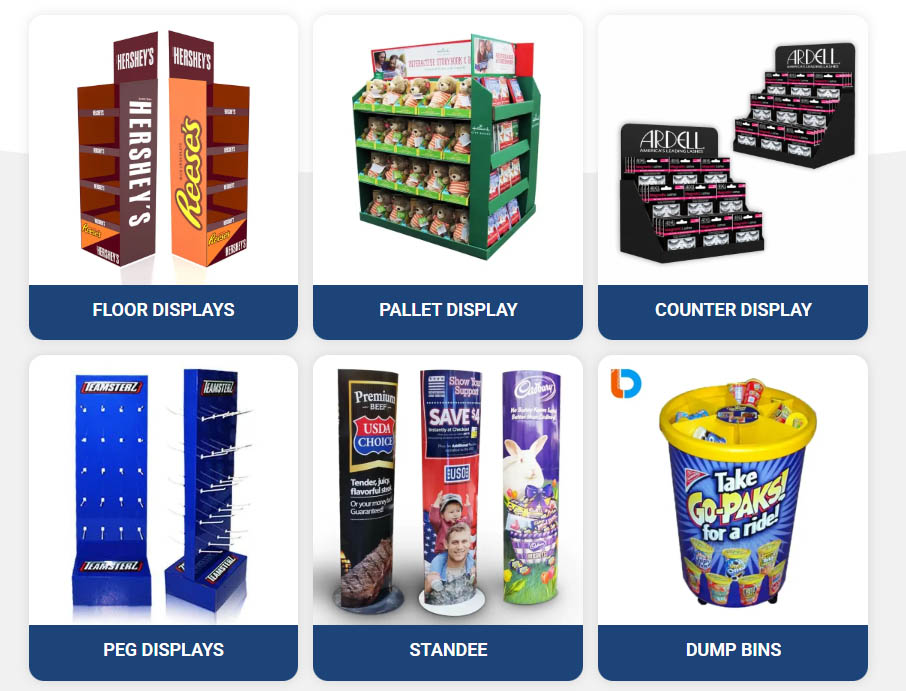

Cardboard displays have many names based on their function and placement. Common industry terms include Point of Purchase (POP)7, Point of Sale (POS), Floor Standing Display Units (FSDU), Counter Display Units (CDU)8, Dump Bins9, and Pallet Displays10.

Learning the language helps streamline the entire design process. I once had a client request a "cardboard thingy for near the checkout." We figured it out, of course, but knowing to ask for a "Counter Display Unit" or "CDU" would have gotten us to the design stage much faster. As a designer, knowing these terms helps you communicate your vision clearly with manufacturers like me. It ensures we are all speaking the same language.

A Glossary for Retail Displays

To avoid confusion, my team and I often start a project by confirming the display type. Each one serves a unique purpose in the retail environment. Understanding them helps in making the right choice for your product and sales strategy.

| Display Name | Common Use Case | Primary Goal |

|---|---|---|

| Floor Display (FSDU) | Placed in store aisles or open spaces. | Showcase a large volume of product, attract attention. |

| Counter Display (CDU) | Sits on checkout counters or shelves. | Encourage last-minute impulse purchases. |

| Pallet Display | Shipped pre-loaded on a pallet for club stores. | High volume sales with minimal setup. |

| Dump Bin | A large, open-top bin for loose or discounted items. | Move clearance items quickly, create a 'treasure hunt'. |

| Endcap Display11 | Designed to fit on the end of a retail aisle. | Highlight promotions or new product launches. |

Having this shared vocabulary is the first step toward a successful collaboration. It removes ambiguity and lets us focus on what really matters: creating a display that sells your product.

What are cardboard display1 boxes?

Need a solution that serves as both a shipping container and a retail display? Designing, producing, and packing separate boxes and displays costs extra time, labor, and money.

A cardboard display1 box is a smart, all-in-one solution. It acts as a protective shipping carton during transit and is designed to quickly convert into a Point-of-Sale display once it reaches the store. These are often called Shelf-Ready Packaging (SRP)12 or Retail-Ready Packaging (RRP).

I'm a huge fan of this design philosophy because it's efficient for everyone. For the brand, it reduces costs. For the retailer, it saves precious time. I’ve seen store staff spend ages trying to unpack products and set up complex displays. A well-designed SRP, however, can be on the shelf in seconds. As designers, our goal is to solve problems, and SRPs solve a big one in the retail chain.

The Art of Smart Conversion

The magic of a display box lies in its structural design13. We incorporate features like perforations14 and tear strips that are strong enough to withstand the bumps of shipping but simple enough for a store employee to open without tools.

Key features we focus on when I design an SRP with my team:

- Easy Identification: The exterior of the box must clearly state what’s inside, so it gets to the right place in the store.

- Simple Opening: We design perforations that are intuitive. A single, clean tear should be all it takes. I call this the "frustration-free" test. If it takes more than 10 seconds to open, it's a failure.

- Instant Display: Once opened, the product should be neatly presented and ready for shoppers to grab. No extra assembly required.

- Easy Disposal: The packaging should be easy to break down and recycle.

This approach requires careful engineering, but the payoff in efficiency and in-store execution is enormous. It’s a perfect example of design thinking15 applied to the entire product lifecycle.

What is the difference between cardboard and corrugated cardboard16?

Are you using the terms "cardboard" and "corrugated" interchangeably? Choosing the wrong material can mean the difference between a sturdy, long-lasting display and one that collapses under pressure.

"Cardboard" is a general term for any heavy paper stock, like a cereal box. "Corrugated cardboard," however, is a specifically engineered material made of three layers: two flat outer sheets (linerboard) and a wavy, arched layer (flute17) sandwiched between them for superior strength.

In my 16 years of experience, this is the most common point of confusion, and it’s the most critical one to clear up. When my clients ask for a "cardboard display1," we almost always build it from corrugated material. The structure of corrugated board provides the strength, rigidity, and cushioning needed to survive in a busy retail environment. Simple paperboard just can't do the same job.

The Unseen Hero: The Flute

The wavy layer in the middle is called the flute, and it's the secret to the material's strength. The arches create air pockets that provide cushioning and add significant structural integrity. Different sizes of these arches, or flutes, are used for different purposes. As a designer, selecting the right flute is a fundamental decision. I had a client who wanted to display heavy bottles of olive oil. A display made from E-flute would have buckled instantly. We needed the strength of a B-flute or even a double-wall BC-flute to handle the weight safely.

| Flute Profile | Thickness (approx.) | Characteristics & Common Uses |

|---|---|---|

| E-Flute | 1.5 mm | Thin profile, excellent print surface. Used for retail boxes and CDUs. |

| B-Flute | 3.0 mm | Good balance of strength and printability. A true workhorse for FSDUs. |

| C-Flute | 4.0 mm | Very common for shipping boxes, offers great cushioning. |

| BC-Flute | 7.0 mm | Double wall (B and C flute17s combined). For heavy-duty pallet displays. |

Understanding this difference is not just technical jargon; it’s fundamental to creating a display that is safe, effective, and represents your brand well.

Conclusion

From design and material choice to manufacturing, creating a successful cardboard display1 is a precise process. Now you know the key steps and terms to bring your vision to life.

-

Explore the concept of cardboard displays and their significance in retail marketing. ↩ ↩ ↩ ↩ ↩ ↩

-

Delve into the process of making paper pulp and its applications in various industries. ↩

-

Find out how lamination enhances the durability and quality of cardboard displays. ↩

-

Understand the significance of virgin fibers in creating high-quality cardboard. ↩

-

Learn about the benefits of using recycled fibers in cardboard manufacturing. ↩

-

Discover how the calendering process affects the quality of paperboard. ↩

-

Learn about POP displays and their effectiveness in driving sales at retail locations. ↩

-

Explore the purpose of CDUs in retail and their impact on consumer behavior. ↩

-

Explore the role of Dump Bins in retail and their effectiveness in clearance sales. ↩

-

Learn about Pallet Displays and their efficiency in showcasing bulk products. ↩

-

Discover how Endcap Displays are strategically used to promote products. ↩

-

Explore the advantages of SRP in retail and how it simplifies product display. ↩

-

Learn about the importance of structural design in creating functional products. ↩

-

Discover how perforations improve the usability of packaging and displays. ↩

-

Explore the principles of design thinking and its impact on innovative solutions. ↩

-

Understand the unique properties of corrugated cardboard and its applications. ↩

-

Learn about the flute structure and its role in providing strength to cardboard. ↩ ↩

One Response