Choosing a new supplier feels risky. A bad choice can damage your product launch and brand reputation. The key is to look for official certifications that prove their quality and reliability.

A trustworthy cardboard display supplier should have certifications like ISO 9001 for quality management systems, FSC for sustainable paper sourcing, and social compliance audits like BSCI or Sedex. These demonstrate a verified commitment to quality, environmental responsibility, and ethical practices, reducing your risk as a buyer.

But what do all these acronyms and logos actually mean for your project? Understanding them is the first step to protecting your investment and choosing a partner who can truly deliver. It's easy to get lost in the details, but knowing the basics can save you from major headaches down the road. Let's break down the most important certifications so you can feel confident in your next supplier decision.

What Are Supplier Certifications?

Have you ever seen a supplier's website covered in logos you don't recognize? It's confusing and hard to know what's important. Let's clarify what these certifications really are.

A supplier certification1 is an official document from an independent third-party organization. It confirms that a supplier's factory, processes, or products meet specific, internationally recognized standards. They provide objective proof of a supplier's claims about quality, safety, or ethical operations, saving you from guesswork.

Think of certifications as a report card for a business. They are not issued by the supplier themselves but by professional, unbiased auditors who visit the factory and perform a thorough inspection. These inspections can cover many different areas, from how the company manages quality control2 to how it treats its workers and its impact on the environment. For me as a buyer, these certifications are incredibly valuable. They significantly reduce the risk of partnering with a new supplier. Instead of just taking their word for it, I have proof from a trusted source. Early in my 16-year career, I learned a tough lesson by choosing a supplier based only on a low price. The displays arrived with major structural problems, and we missed a critical launch date for a client. That costly mistake taught me that third-party verification3 isn't a "nice-to-have"—it's an absolute must. Certifications are now the very first thing I look for.

What Are the Two Main Types of Certifications?

All the different certifications can seem overwhelming. It can be hard to know which ones matter for your specific project. Thankfully, they generally fall into two simple and distinct categories.

Supplier certifications are usually either process-based or product-based. Process-based certifications, such as ISO 9001, focus on the company's internal management systems. Product-based certifications, like UL or CE, verify that a specific item meets certain safety and performance standards. Both types are important for different reasons.

Let's dive deeper into these two types. Process-based certifications look at how a company operates. They ensure the supplier has reliable systems in place to achieve consistent results. For instance, ISO 9001 confirms they have a quality management system to prevent errors, while FSC (Forest Stewardship Council) certifies their "chain of custody" process, proving their paper is tracked from a sustainable forest. On the other hand, product-based certifications4 examine the final product itself. This is more common for products with electronics or safety risks. For cardboard displays, which are generally inert, process certifications are often more telling about the supplier you're dealing with. However, a certification like ISTA (International Safe Transit Association) testing could be considered a product-level verification, as it tests the packaging's ability to protect the product during shipping.

| Feature | Process-Based Certification | Product-Based Certification |

|---|---|---|

| Focus | The company's systems & procedures | The final product itself |

| Example | ISO 90015, FSC6, BSCI7 | CE, RoHS (for electronics) |

| What it tells you | The supplier is reliable, consistent, and organized. | The specific item is safe and meets technical standards. |

| Relevance | Always important for choosing a good partner. | Critical if your display includes electronics or has safety requirements. |

What Key Quality Certifications Should I Look For?

You know you need a high-quality product. But how can you be sure a new supplier can deliver that quality every single time? The answer lies in a few key certifications.

For a cardboard display supplier, the most critical quality certification is ISO 9001. This standard proves they have a solid Quality Management System (QMS). Next, FSC certification is essential, as it verifies that their paper materials come from responsibly managed forests, reflecting both quality and sustainability.

ISO 9001 is the international gold standard for quality management. It means the supplier doesn't just hope for good results; they have documented processes for everything from initial design to final shipment. They are required to track mistakes, analyze why they happened, and take corrective action to prevent them from reoccurring. This systematic approach leads to fewer defects, more consistent products, and more reliable delivery schedules. A few years ago, my company secured a huge order for a national retailer. The complexity was enormous, but our ISO 9001 system was the backbone of the operation. Every step was documented and checked. The client was amazed by the perfect execution. That's why I say it is not just a piece of paper; it’s our blueprint for success. Similarly, FSC certification speaks directly to the quality and integrity of the raw materials, ensuring your brand is associated with environmental responsibility8.

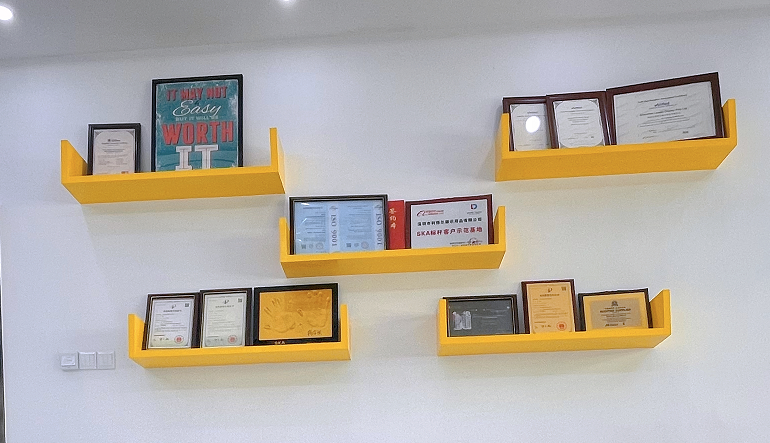

How Can I Create My Own Supplier Vetting Process?

Relying only on third-party certifications might not feel like enough. You want extra assurance that a supplier can meet your specific needs. The solution is to build your own simple vetting process9.

To establish your own supplier vetting program, start by defining your "must-have" criteria, such as quality, sustainability, or social compliance. Next, request copies of key certifications like ISO 9001, FSC, and BSCI. Finally, consider placing a small trial order to directly evaluate their performance.

Creating a structured process empowers you to make better choices. Here is a simple way to do it. First, list your non-negotiable requirements. Is environmental impact your top priority? Then FSC is a must. Do you need perfect consistency for a high-end brand? Then ISO 9001 is essential. Is your brand’s reputation built on ethical sourcing? Then look for a recent BSCI or Sedex audit. Second, turn this list into a simple checklist you can use for every potential supplier. Ask them to provide copies of the actual certificates, not just the logos on their website. A good checklist might include: Has ISO 9001? (Y/N), Provide certificate number, Has FSC? (Y/N), Provide certificate number. Third, go beyond the certificate. Ask for the most recent audit report10. A certificate shows they passed an audit, but the report gives details. A transparent supplier will share this and explain how they fixed any issues. This shows they are serious about continuous improvement.

Conclusion

Supplier certifications like ISO 9001 and FSC are not just for show. They are essential proof of a supplier's commitment to quality, reliability, and ethics, helping you choose right.

-

Understand the advantages of supplier certifications in ensuring quality and reliability. ↩

-

Learn about the role of quality control in maintaining high product standards. ↩

-

Understand the importance of third-party verification in ensuring supplier credibility. ↩

-

Discover the significance of product-based certifications in ensuring product safety and quality. ↩

-

Explore this link to understand how ISO 9001 can enhance quality management in your supply chain. ↩

-

Learn about FSC certification and its role in promoting responsible paper sourcing and environmental sustainability. ↩

-

Discover how BSCI certification helps ensure ethical labor practices in your supply chain. ↩

-

Explore the concept of environmental responsibility and its importance in modern business. ↩

-

Discover steps to establish a robust supplier vetting process for better decision-making. ↩

-

Find out what to look for in an audit report to assess supplier performance. ↩