Struggling to find a reliable cardboard display manufacturer? Choosing the wrong partner can lead to poor displays and wasted money. Let me share my 16 years of experience to help you.

When choosing a cardboard display manufacturer, look for their industry experience and portfolio. Check their design and engineering skills, material quality, and production capabilities. Also, ensure they have strong communication, transparent pricing, and a clear process from start to finish. This guarantees a successful partnership.

Choosing the right partner is a big decision. It’s about more than just a good price. You need someone who understands your vision and can bring it to life without any hassle. Let’s break down the key areas you need to examine to make the best choice. This will save you a lot of headaches later on.

How Can You Verify a Manufacturer's Design Capabilities and Experience?

Worried a manufacturer can't handle your unique design ideas? A weak design team means your display might be flimsy or look generic. Verifying their experience and design skills is crucial.

To verify a manufacturer's design skills, ask for their portfolio and case studies of similar projects. Inquire about their design team's experience and the software they use. A good partner will offer structural design consultations and provide samples or prototypes to prove their capabilities before mass production.

A great display starts with a great design. But a great design is not just about looks; it's also about a solid structure. The manufacturer you choose should have both creative graphic designers and skilled structural engineers. I remember working with a product designer named Peter. He had a brilliant idea for a multi-tiered display for a new snack brand but was worried it wouldn't be strong enough to hold the product weight. We first showed him our 3D renderings to visualize the structure. Then, we created a full-size physical prototype. Seeing it and testing it with his products gave him the confidence to approve the project. This is the kind of partnership you want. A good manufacturer invests in their design team and is happy to prove their skills with a real sample.

Key Areas to Check

| Feature | What to Ask | Why It Matters |

|---|---|---|

| Portfolio | "Can I see examples of projects in my industry?" | This shows relevant experience and past successes. |

| Design Team | "Who will be designing my display? What's their experience?" | You want an experienced team that understands structural integrity. |

| Prototyping | "Do you offer physical samples before mass production?" | This allows you to test the design and make changes before committing. |

What Production Quality and Material Options Should You Expect?

Afraid your displays will look cheap or fall apart? Poor materials can lead to displays collapsing in-store, damaging your products and brand reputation. Knowing what to look for is essential.

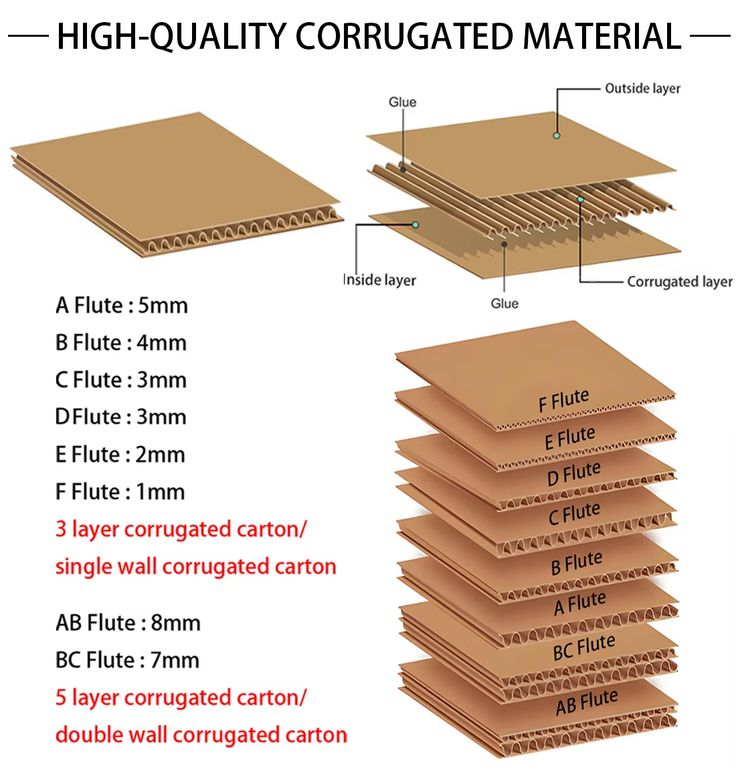

Expect a good manufacturer to offer various cardboard grades, like B, E, or F flute, and options like corrugated or paperboard. They should have clear quality control processes, including color matching and structural tests. Ask about sustainable materials and certifications to ensure responsible sourcing.

The material you choose directly impacts your display's strength, appearance, and cost. Your manufacturer should guide you through the options, not just sell you the cheapest one. Years ago, we had a project for a cosmetics line. The client wanted a high-gloss, premium finish. The first batch of prints didn't pass our internal quality control for color consistency. The shade was just slightly off from their brand guidelines. We immediately stopped production, recalibrated our printers, and redid the entire run. It caused a slight delay, but the client was thrilled with the final, perfect product. A good manufacturer takes full responsibility for quality. They have systems in place to catch errors before they become your problem. They should be proud to tell you about their QC process.

Understanding Material Types

Different products and retail environments require different materials. For example, B-flute corrugated board is strong and great for holding heavier items. E-flute has a smoother surface, which is better for high-quality printing. You can also add coatings, like glossy or matte lamination, to protect the display and make it look more professional.

The Importance of Quality Control

A reliable partner will inspect for quality at every step. This includes checking the raw materials, reviewing the first print samples, and inspecting the final products for structural defects before they are packed and shipped. This ensures every display meets your standards.

How Important Are Communication and Customer Service in the Process?

Frustrated by slow responses and unclear updates from suppliers? Poor communication leads to misunderstandings, missed deadlines, and a final product that doesn't match your vision. It's a huge problem.

Communication is critical. A great manufacturer provides a dedicated contact person, gives regular updates, and is responsive to your questions. They should listen to your needs and proactively solve problems. Good service ensures the project stays on track and meets your exact specifications without any surprises.

I always tell my team that our job is 50% making displays and 50% communication. You could have the best designers and machines in the world, but if you can't communicate well with your client, the project will fail. I once worked with a client on a tight deadline for a big trade show. A shipping delay on raw materials threatened the timeline. Instead of hiding the problem, we called the client immediately. We explained the situation and offered a solution to expedite the printing process once the materials arrived. They appreciated the honesty, and we still met their deadline. That’s what a true partnership looks like. You want a manufacturer who sees you as a partner, not just another order. They should be transparent, honest, and always working with you to find the best solutions.

What Good Communication Looks Like:

- Dedicated Account Manager: You should have one person who knows your project inside and out. You shouldn't have to explain your needs to a different person every time you call.

- Regular Updates: You should receive proactive updates on the design, production, and shipping stages without having to ask for them.

- A Problem-Solving Attitude: When challenges appear, they shouldn't just state the problem. They should come to you with potential solutions already in mind.

What Should You Know About Pricing, Lead Times, and Shipping?

Confused by complex quotes and worried about hidden costs? Unexpected fees and long delays can ruin your budget and your entire product launch campaign. You need a clear and predictable process.

Always ask for a detailed quote that breaks down all costs: design, samples, production, and shipping. Clarify lead times for each stage and understand their shipping capabilities. A transparent partner will explain pricing variables like quantity and complexity, ensuring there are no hidden fees.

Understanding the full cost is more than just looking at the per-unit price. I always advise clients to think about the total cost of ownership. For example, shipping displays flat-packed is cheaper, but you have to factor in the assembly time and cost on your end. Sometimes, paying a little more for pre-assembled displays saves you money in the long run. A good manufacturer will walk you through these options patiently. They will explain how your order quantity changes the price and what you can expect for lead times. When we work with clients like Peter, we aim to find the most cost-effective solution for their entire supply chain, not just for the display itself. Transparency in pricing and scheduling builds trust and prevents nasty surprises.

Understanding Your Quote

A clear quote should break everything down for you. Here are some common components to look for:

| Cost Component | Description | Tip |

|---|---|---|

| Tooling/Die-cut | This is a one-time fee for creating the custom cutter for your display shape. | Ask if this is a one-time charge or if it applies to reorders. |

| Per-Unit Price | This is the cost for each individual display. | This price usually decreases as your order quantity increases. |

| Shipping | This is the cost to get the displays from the factory to your warehouse. | Clarify if this cost is for flat-packed or pre-assembled units. |

Conclusion

Choosing the right manufacturer comes down to verifying their experience, quality, communication, and pricing. Do your homework, ask the right questions, and you'll find a partner to help you succeed.