Feeling lost ordering custom displays? The wrong questions lead to bad results and wasted money. Here are the essential questions to ask your supplier before you commit to anything.

You should ask about material options, structural design limitations, printing capabilities, turnaround times, and pricing for different quantities. Key questions cover durability, assembly, and shipping logistics to ensure project success.

Getting the right display is about more than just a good price. It's about asking the right questions from the start. I've spent 16 years in this business, and I've seen how a few simple questions can prevent major headaches down the line. Let's dive into some of the most fundamental questions I get asked, starting with the basics of what these displays are even called. This will build a solid foundation for our conversation.

What are cardboard displays called?

Ever feel like you're not speaking the same language as your display supplier? This leads to confusion and mistakes. Let’s learn the correct terms for cardboard displays.

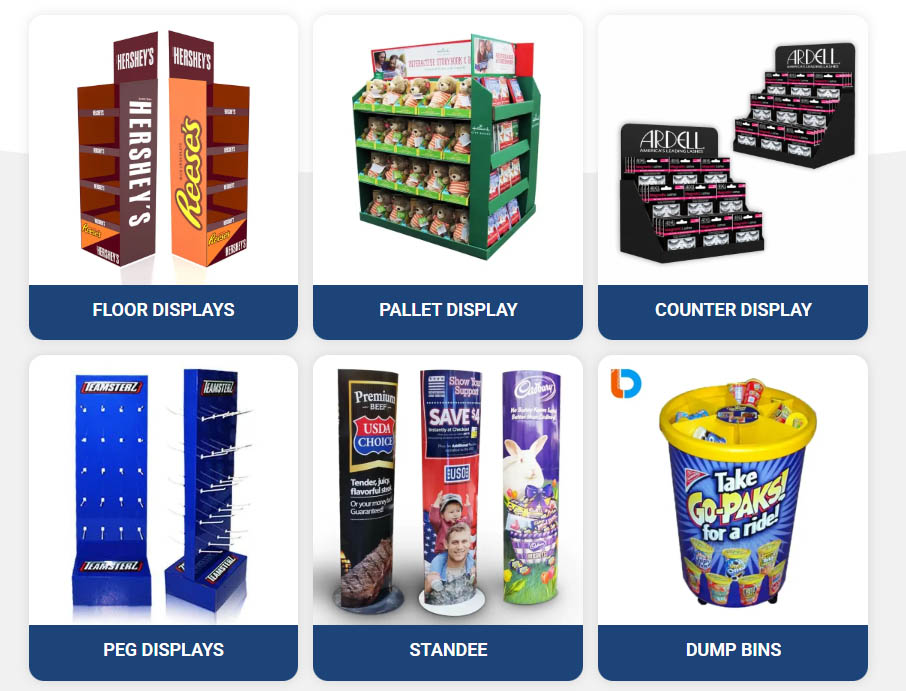

Cardboard displays are often called Point of Purchase (POP) displays1 or Point of Sale (POS) displays2. Other common names include temporary displays3, floor stands, counter displays, or shipper displays, depending on their specific form and function in a retail environment.

Demystifying Display Terminology

The names for cardboard displays often describe where they are used or what they do. The most common umbrella terms are "Point of Purchase" (POP) or "Point of Sale" (POS). They basically mean the same thing: a display designed to attract customers right where they are making a buying decision. I've worked with hundreds of clients, and clarifying these terms is always our first step. It helps everyone get on the same page quickly.

Common Display Types Explained

| Understanding the specific names helps you communicate your needs clearly. For a product designer like Peter, using the right term is essential for getting an accurate quote and concept. | Display Type | Typical Location | Primary Use |

|---|---|---|---|

| Floor Display | In store aisles | Standalone unit to showcase products. | |

| Counter Display | On checkout counters | For smaller, impulse-buy items. | |

| Pallet Display | On a pallet | For high-volume, bulk products. | |

| Endcap Display | At the end of aisles | To promote sales or new items. | |

| Shipper Display | A shipping box that converts to a display | To reduce handling and setup time. |

Knowing these terms helps you and your designer get on the same page instantly.

What are cardboard display boxes?

Need a display that's also the shipping box? Using two separate boxes is costly and inefficient. Cardboard display boxes are a smart two-in-one solution for any product.

A cardboard display box, often called a Retail-Ready Package (RRP)4 or a Shelf-Ready Package (SRP)5, is a dual-purpose container. It functions as a protective shipping box and can be easily converted into an organized, attractive display on the retail shelf or counter.

The Smart Design of Display Boxes

I remember a project with a candy company. They were shipping products in plain boxes, and retail staff had to unpack every single candy bar to stock the shelves. It was a huge time sink. We designed a Shelf-Ready Package (SRP) for them. The box arrived sealed, the staff just tore off a perforated front panel, and the display was ready. Sales went up because the presentation was always neat and tidy.

What to Look for in a Display Box

A good display box is a masterpiece of smart design. As a designer like Peter knows, it has to balance several needs.

- Easy Opening: It should be simple for store staff to open without tools. Perforations and tear strips are common features for this.

- Clear Branding: Even as a shipper, the box should have some branding. Once opened, it must clearly display the product and brand message.

- Durability: The box must be strong enough to survive shipping but still easy to convert into a display.

This design approach saves time for the retailer and ensures your product always looks great on the shelf.

What are the three types of cardboard?

Think all cardboard is the same? Choosing the wrong type means your display might fail, or you’ll overspend. Let's cover the three main types of cardboard.

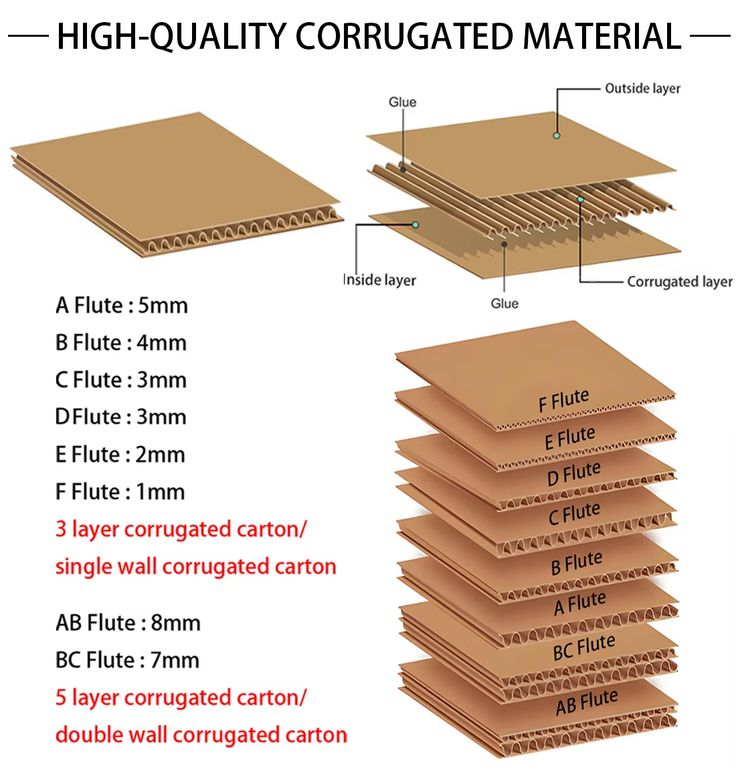

The three main types of cardboard used for displays are paperboard (for light items), single-wall corrugated6 (most common), and double-wall corrugated7 (for heavy-duty displays). Your choice depends on the weight and size of your products and the needed display durability.

A Closer Look at Cardboard Materials

When a client comes to me, one of the first things we discuss is product weight. A display for light cosmetic boxes is very different from one holding bottles of olive oil. The material choice is critical. For a designer like Peter, specifying the right material is a fundamental part of a successful project. It's about finding the sweet spot between structural integrity and budget.

Choosing the Right Cardboard for Your Display

| Here’s a simple breakdown to help you understand the options. | Cardboard Type | Structure | Best For |

|---|---|---|---|

| Paperboard | A single, thick layer of paper. | Lightweight items like greeting cards, small cosmetics, or candy packets. | |

| Single-Wall Corrugated | Two flat liners with a wavy "flute" layer in between. | The most versatile option for floor stands and counter displays holding products like snacks or toys. | |

| Double-Wall Corrugated | Three flat liners with two flute layers. | Heavy items like beverage bottles, canned goods, or electronics. Provides maximum strength. |

Choosing the right one ensures your display is both safe and cost-effective. You don't want to pay for strength you don't need.

How to make a cardboard stand for a display?

Wondering how a display is made? Not knowing the process can cause delays and frustration with your supplier. Let's walk through the steps from concept to final creation.

Creating a cardboard display involves several key stages: conceptual design and structural engineering, creating a die-line, graphic design, printing, die-cutting8 the cardboard sheets, and finally, folding and gluing. Each step is crucial for producing a functional and attractive final stand.

The Journey of a Custom Display

I've overseen thousands of display projects, and the process is a fascinating blend of art and engineering. For designers like Peter, this is where their digital creations become tangible. It starts with a simple conversation about the product and the retail environment. We need to know where it will go, how much weight it will hold, and who will be setting it up. This information is the foundation for everything that follows.

The Manufacturing Steps Explained

Here’s a simplified look at how we bring a display stand to life:

- Structural Design: We create a 3D model and a flat template, called a die-line. This design ensures the stand is strong and stable.

- Graphic Design: Your artwork is applied to the die-line template.

- Prototyping: We make a physical sample to test for fit, function, and strength.

- Printing: Once approved, we print your artwork onto large sheets of cardboard.

- Die-Cutting: A custom tool, like a giant cookie-cutter, cuts the printed sheets into the final shapes.

- Finishing: The cut pieces are folded, glued, and assembled into the final flat-packed display, ready for shipping.

Conclusion

Asking these questions about terminology, types, materials, and processes will help you partner with your supplier effectively. It ensures you get the perfect custom cardboard display for your specific needs.

-

Discover the advantages of POP displays in attracting customers at the point of sale. ↩

-

Learn how POS displays can enhance your retail strategy and boost sales. ↩

-

Understand the purpose of temporary displays to make informed decisions for your marketing. ↩

-

Explore the benefits of RRPs for efficient product display and shipping. ↩

-

Learn how SRPs can simplify your retail operations and improve product visibility. ↩

-

Discover the versatility of single-wall corrugated cardboard for various display needs. ↩

-

Understand when to use double-wall corrugated cardboard for heavy-duty displays. ↩

-

Learn about die-cutting techniques that can enhance the design and functionality of your displays. ↩