Struggling to find a reliable cardboard display supplier? A wrong choice can ruin your launch and hurt your budget. Here's a simple checklist to find the perfect partner.

The best cardboard display suppliers offer more than just a low price. You should look for a partner with proven design and engineering expertise, robust manufacturing capabilities, clear communication, and a strong commitment to quality and sustainability. They should act as a true extension of your team.

Choosing a supplier is a big decision. It’s about finding a partner who understands your vision and can bring it to life effectively. After 16 years in this industry, I've learned exactly what separates the great suppliers from the rest. This checklist is built from my experience helping clients just like you. Let's break down the essential things you need to look for. This will help you make the right choice every time and avoid costly mistakes.

How Important is Design and Engineering Expertise?

Have a great display idea but worried it won't work in reality? A supplier without strong engineering skills can turn your vision into a production nightmare, wasting time and money.

This expertise is critical. A great supplier combines creative design with solid structural engineering. They ensure your display is not only eye-catching but also strong, stable, and easy to assemble in the store. This prevents product damage and ensures a successful retail presence.

When I work with product designers like Peter, I know they appreciate a supplier who speaks their language. It's not just about looks; it's about function. Your supplier's design team must be able to translate your creative concepts into structurally sound displays. They need deep knowledge of materials and how they perform under stress. A good partner will proactively suggest improvements to your design to enhance strength, reduce costs, or simplify assembly. Before you commit, ask them about their process.

Key Design and Engineering Questions

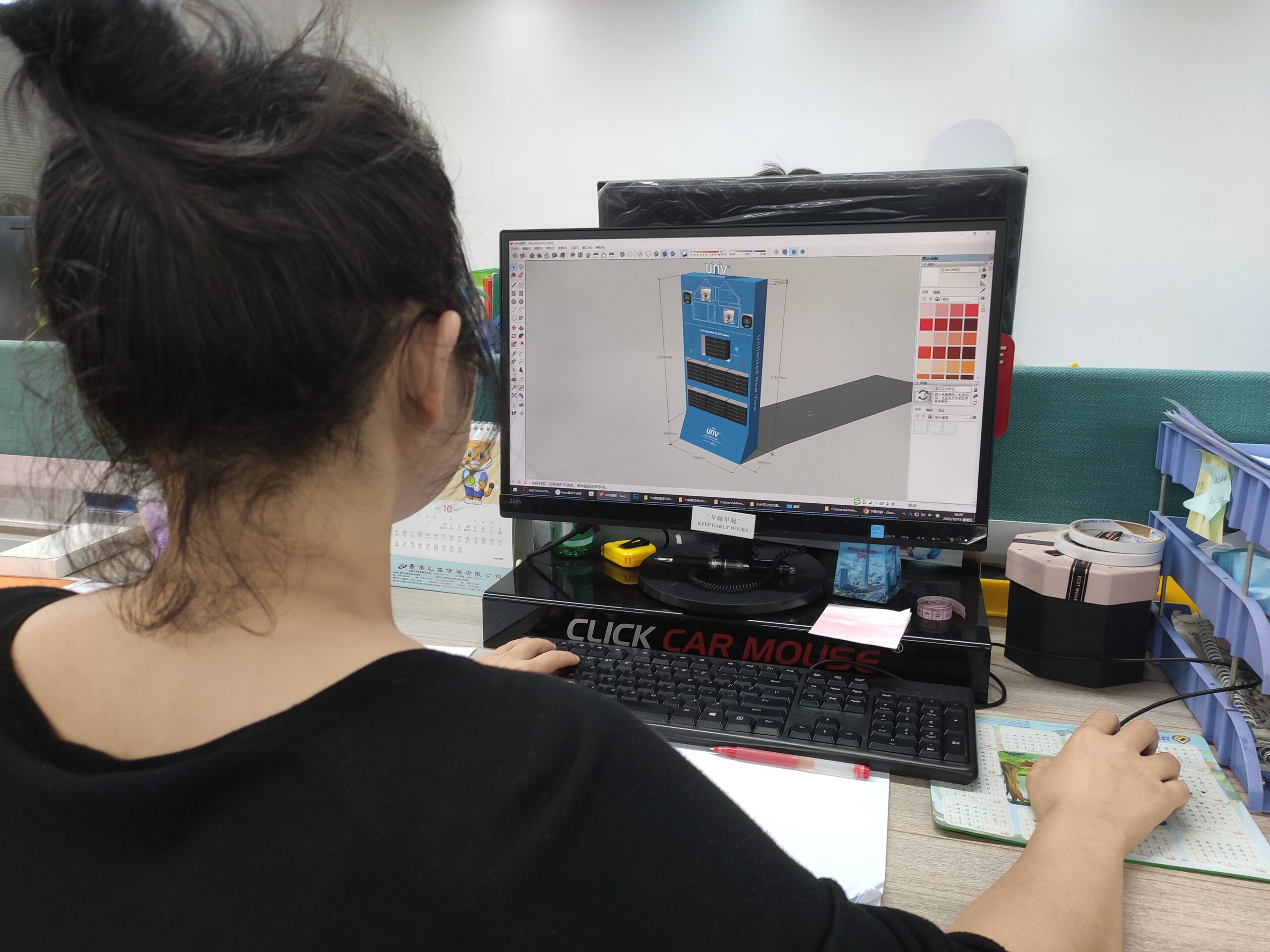

- Prototyping: Do they offer physical prototypes? A 3D render is good, but a physical sample is the only way to truly test the design's strength and functionality.

- Collaboration: How do they work with your design team? Look for a partner who uses collaborative tools and values your input throughout the process.

- Problem-Solving: Ask for an example of a time they solved a complex structural challenge for a client.

Here is a simple table to compare potential suppliers:

| Feature | Supplier A | Supplier B | Ideal Supplier |

|---|---|---|---|

| In-House Engineers | Yes | No | Yes, dedicated structural design team. |

| CAD & 3D Software | Yes | Yes | Proficient in modern design software. |

| Prototyping Service | Yes | Limited | Offers rapid and accurate physical samples. |

| Material Expertise | Moderate | High | Deep knowledge of various corrugated grades. |

A supplier with strong engineering skills doesn't just build your design; they improve it. They become an invaluable resource, helping you avoid problems before they happen.

What Should You Expect from Their Manufacturing Capabilities?

Your design is approved, but can the supplier actually produce it at scale? Poor manufacturing leads to missed deadlines, inconsistent quality, and a failed retail launch that reflects badly on you.

You should expect modern equipment, strict quality control, and the capacity to meet your deadlines without compromising on quality. A capable manufacturer has a clean, organized facility and can show you examples of their work, proving they can handle your project from start to finish.

As someone who lives and breathes this industry, I always invite potential clients to see our facility. The state of a factory tells you everything. You want to see modern printing and die-cutting machines that ensure precision and vibrant colors. You also want to see a clear workflow, from raw material intake to final packing. A disorganized factory often means disorganized production and a higher chance of errors. Ask about their production capacity. Can they handle your volume, especially during peak seasons? A good partner will be transparent about their capabilities and limitations.

Evaluating Production Power

- Quality Control (QC): What does their QC process look like? There should be checks at every stage: printing, cutting, gluing, and packing.

- Scalability: Can they handle a small test run of 50 units as well as a full production run of 5,000? Flexibility is key.

- Technology: What kind of printing technology do they use? Digital printing is great for short runs and complex graphics, while offset printing is more cost-effective for large volumes.

Here’s a quick reference for what to look for:

| Manufacturing Aspect | Red Flag | Green Flag |

|---|---|---|

| Printing | Outdated machines, inconsistent colors | Modern CMYK or Pantone printing, clear color proofs. |

| Cutting | Manual cutting, rough edges | Automated die-cutting for precision and consistency. |

| Assembly | Confusing instructions, missing parts | Kitting services, clear instructions, pre-assembly. |

| Lead Times | Vague or consistently long promises | Clear, reliable production schedules. |

Your supplier’s factory is where your vision becomes reality. Make sure they have the right tools, processes, and people to get the job done right.

Why Does Communication and Project Management Matter So Much?

Feeling lost in the dark about your project's status? Poor communication creates stress, leads to misunderstandings, and can derail your entire timeline. You deserve clarity and confidence.

Excellent communication is non-negotiable. It ensures everyone is aligned, from your team to their production floor. A great partner provides a dedicated point of contact, regular updates, and a clear project timeline. This proactive approach prevents surprises and keeps your project on track.

I've learned over the years that building a great display is only half the battle. The other half is managing the project smoothly. For a designer like Peter, who has to coordinate between clients, sales, and production, having a reliable contact at the supplier is a game-changer. This person should be your champion within their organization. They should understand your goals, anticipate your needs, and solve problems quickly. You shouldn't have to chase them for updates. A professional supplier will have a system in place for project management, whether it's through a shared portal, regular emails, or weekly calls.

Hallmarks of a Great Communicator

- Dedicated Contact: You should have one main person responsible for your project who knows every detail.

- Responsiveness: How quickly do they respond to your emails or calls? Timely answers are a sign of a well-run operation.

- Transparency: Are they honest about potential issues or delays? A true partner tells you the bad news just as quickly as the good news, along with a plan to fix it.

Here’s a simple checklist to assess a supplier's communication style:

| Communication Trait | What to Look For | Why It Matters |

|---|---|---|

| Clarity | Simple, direct language. Avoids jargon. | Reduces misunderstandings and ensures everyone is on the same page. |

| Proactiveness | Provides updates before you have to ask. | Shows they are managing your project, not just reacting to it. |

| Accessibility | Easy to reach the project manager during business hours. | Allows you to resolve urgent issues quickly and efficiently. |

| Documentation | Provides clear quotes, timelines, and change orders. | Creates a clear paper trail and holds everyone accountable. |

When you have a supplier who masters communication, you can focus on your own work, confident that your project is in good hands.

How Do You Evaluate Their Commitment to Quality and Sustainability?

Worried your displays will arrive damaged or look cheap? Or that they are made from unsustainable materials? Low-quality production and a disregard for the environment can damage your brand's image.

Evaluate their commitment by checking their quality control certifications, asking for material sourcing information, and reviewing their portfolio. A top-tier supplier proudly showcases their quality standards, uses eco-friendly materials, and has a track record of delivering durable, high-end products.

In today's market, quality and sustainability are not optional—they are essential. Your customers, and in turn your retail partners, expect them. As a business owner, I'm proud of the certifications we've earned, like ISO 9001, because they represent our promise to clients. When evaluating a supplier, ask to see their quality management credentials. Also, ask about their material sourcing. Do they use recycled paper? Are their inks soy-based or water-based? A supplier committed to sustainability will have these answers ready. This is not just about being green; it’s about responsible business practices that protect your brand’s reputation.

Verifying Quality and Green Credentials

- Certifications: Look for internationally recognized standards like ISO 9001 (for quality management) and FSC (Forest Stewardship Council) for responsible paper sourcing.

- Material Specs: Ask for detailed specifications on the cardboard they use. What is the recycled content percentage? Is it fully recyclable?

- Waste Reduction: Inquire about their manufacturing process. How do they minimize material waste and energy consumption? A good supplier optimizes cutting layouts to reduce scrap.

This table can help you score their commitment:

| Area | Basic Supplier | Excellent Supplier |

|---|---|---|

| Quality | Claims to have "good quality." | Shows ISO 9001 certification, has a documented QC process. |

| Materials | Uses standard board. | Offers high-recycled content board, FSC-certified options. |

| Inks & Glues | Uses standard, solvent-based inks. | Uses vegetable- or water-based inks and eco-friendly glues. |

| End-of-Life | Leaves disposal to the retailer. | Designs for easy disassembly and recycling. |

Choosing a partner who prioritizes quality and sustainability protects your investment, enhances your brand image, and shows your customers that you care.

Conclusion

Finding the right cardboard display packaging supplier is about finding a partner. Focus on expertise, capability, communication, and quality to ensure your brand and product shine at retail.