Struggling to choose the right material for your cosmetic display? A poor choice can lead to a weak brand presentation. Understanding the differences is key to making the right decision.

Corrugated displays are built for durability and heavier products, ideal for long-term campaigns. Standard cardboard (paperboard) displays offer superior print quality for fine details and are more cost-effective for short-term, lightweight promotions. Your choice depends on campaign length, product weight, and budget.

Choosing the right display is one of the most important decisions for a product launch. I've seen brands make this choice based on cost alone, and it can backfire. You need to think about where the display will be, how long it needs to last, and what it needs to hold. Let's break down the key factors to help you decide which material is best for your beautiful cosmetic products. Making the right call here ensures your display works hard for your brand from day one.

Which Display Lasts Longer on a Busy Shop Floor?

You’ve invested in a beautiful display, but it starts to look worn out after just a few days. This can damage your product's image. Let's look at which material holds up.

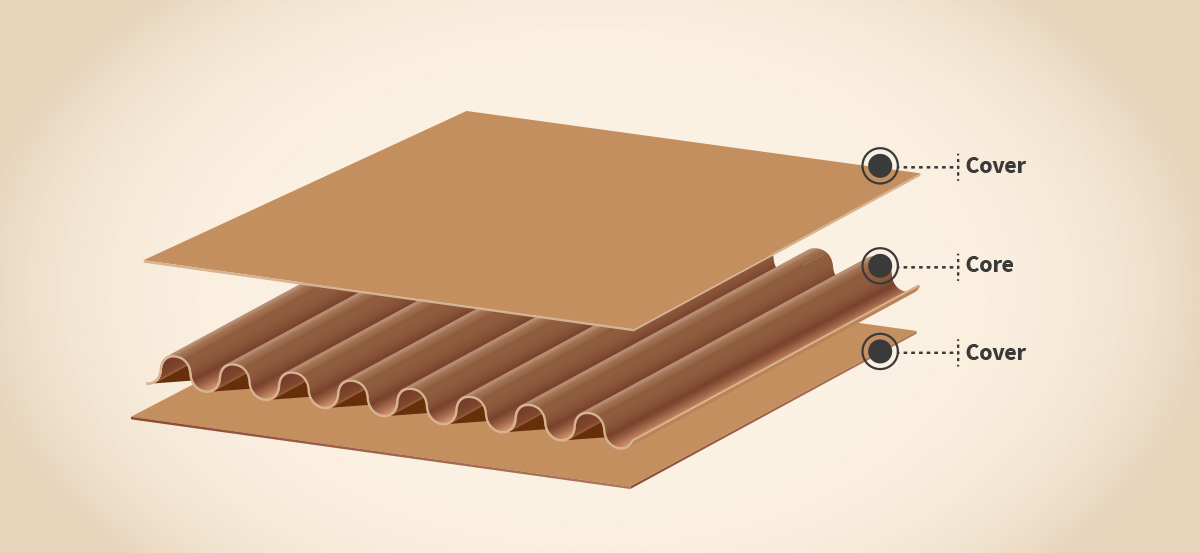

Corrugated displays are much stronger and last longer. Their unique S-flute inner layer provides structural support that single-layer cardboard lacks. This makes them the best choice for high-traffic retail environments or for campaigns lasting more than a week.

I remember a client launching a new line of serums. They needed a counter display to hold about 15 glass bottles. They initially leaned towards a simple cardboard design because of the look. I advised them that the weight of the bottles and the constant customer interaction would be too much for it. We switched to a B-flute corrugated design. Six weeks later, the display was still standing strong, looking as good as new. The structure of corrugated board is its secret weapon. It has one or more wavy, fluted layers sandwiched between flat linerboards. This design creates a series of connected arches, making it incredibly strong and resistant to bending and pressure. Standard cardboard, which is often called paperboard, is just a single, thick sheet of paper. It's great for boxes but lacks the structural integrity needed to hold weight over time.

Durability Breakdown

| Feature | Cardboard (Paperboard) | Corrugated Board |

|---|---|---|

| Structure | A single, solid paper layer | Multiple layers with a fluted core |

| Strength | Best for very lightweight items | Can support significant weight |

| Longevity | Short-term (days to a week) | Long-term (weeks to months) |

| Best For | Light items like single eyeshadows | Heavier items like foundation bottles |

For any display that needs to survive in a busy retail space or hold more than a few lightweight items, corrugated is the only reliable option.

How Do Printing Finishes Differ Between the Two Materials?

You have a stunning design, but the final printed display looks faded and cheap. This fails to attract customers. Choosing the right material for your graphics is crucial for visual impact.

Cardboard, with its smooth, non-porous surface, is perfect for high-resolution graphics and photorealistic images. Corrugated board can have a slightly uneven surface, but advanced litho-lamination techniques allow it to achieve a premium, high-quality finish comparable to cardboard.

A luxury skincare brand I worked with wanted to feature a close-up, dewy portrait on their new display. The detail was incredibly important. We chose a solid bleached sulfate (SBS) paperboard for its super-smooth, bright white surface. The result was amazing; the print was crisp, and the colors were vibrant, perfectly matching their premium brand image. The printing process is what really sets these materials apart. With cardboard, we can print directly onto the surface using offset or digital methods, which is perfect for fine text and intricate designs. For corrugated, we have a couple of options. We can print directly onto it, which is cost-effective for simple, bold graphics. Or, for a high-end look, we use a process called litho-lamination. We print the design on a high-quality paper sheet and then glue it onto the corrugated board. This gives you the strength of corrugated with the print quality of paperboard.

Printing Comparison

| Printing Aspect | Cardboard (Paperboard) | Corrugated Board |

|---|---|---|

| Surface | Very smooth and even | Can have slight ridges from flutes |

| Best for | Photorealistic images, fine text | Bold logos, larger graphics |

| High-End Finish | Achieved with standard printing | Achieved via litho-lamination |

| Visual Result | Crisp, sharp, and detailed | Strong and bold, or premium |

So, if your design is highly detailed, cardboard is a natural fit. If you need strength but refuse to compromise on visuals, litho-laminated corrugated is the perfect solution.

Which Option Offers Better Value for Your Marketing Budget?

Every marketing team has a tight budget. Spending too much on a display that doesn't last is a waste. Let's compare the costs to see which offers better long-term value.

Cardboard displays have a lower upfront cost, making them ideal for short-term promotions or limited budgets. Corrugated displays cost more initially but provide better value over time because their durability means they do not need to be replaced as often.

I often talk to designers like Peter who are balancing creative ideas with practical budgets. He once had a client who needed hundreds of small displays for a one-weekend promotional event. The goal was maximum visibility for minimal cost. We went with a simple, die-cut cardboard counter display. It was cheap to produce, easy to ship flat, and served its purpose perfectly for those three days. The key is to think about the display's total lifespan. Cardboard is cheaper per unit. The material costs less, and it’s simpler to produce. However, if a cardboard display in a busy store gets damaged after a week, you have to pay for a replacement. A corrugated display might cost 30-50% more upfront, but if it lasts for the entire eight-week campaign, you’ve saved money and a lot of hassle. The return on investment for corrugated is much higher for any promotion that isn’t extremely short.

Budget and Value Analysis

| Cost Factor | Cardboard (Paperboard) | Corrugated Board |

|---|---|---|

| Upfront Cost | Lower | Higher |

| Cost Over Time | Can be high due to replacements | Lower due to high durability |

| Best for | Tight budgets, short events | Value-focused, longer campaigns |

| ROI | High for very short promotions | High for promotions over a week |

I always tell my clients to define the campaign's duration first. "Cheaper" is not always better value. Investing a little more in a corrugated display often pays for itself by standing strong and looking great for the entire campaign.

Conclusion

Ultimately, the best choice between cardboard and corrugated displays depends entirely on your campaign’s specific needs for durability, print quality, and budget.