Struggling to make your hats stand out in a crowded store? Traditional displays are bulky and expensive. I will show you how a smart cardboard display can grab attention and boost your sales.

To create a cardboard hat display that sells, focus on a design that complements your hat style, uses durable materials like corrugated B-flute, and features clear branding. This ensures your display is a powerful sales tool that attracts customers, not just a holder.

That's the short answer, but there is so much more to it. I have spent 16 years in the commercial display and packaging industry, and I have learned that the small details make the biggest difference. A great display doesn't just hold products; it tells a story and connects with the customer. Let's break down how you can go from a basic idea to a display that helps hats fly off the shelves.

What design choices make a hat display truly effective?

Ever design a display that looked great on screen but failed in the store? It is frustrating when a design does not connect with shoppers. Let's explore how to fix that problem for good.

An effective hat display design considers the type (counter, floor, or wall-mounted), the hat's unique shape, and the target customer. Prioritizing visibility and easy access ensures customers can interact with the hats, which is crucial for turning interest into a purchase.

I have seen countless designs over the years, and the most successful ones always start with a deep understanding of the product and the environment. Hats are not simple boxes. They have unique shapes, sizes, and personalities. Your display needs to respect that. For a designer like Peter, thinking beyond the aesthetics and focusing on function is key. It's a balance between creativity and engineering.

Choosing the Right Display Type

The first decision is where the display will live in the store. This choice affects everything from size to material. Each type has its own strengths, and picking the right one is your first step toward success. Here is a simple breakdown I use with my clients:

| Display Type | Best For | Pros | Cons |

|---|---|---|---|

| Countertop | Point-of-sale, checkout areas, small spaces. | Grabs impulse buyers, easy to place. | Limited capacity, can create clutter. |

| Floor (FSDU) | High-traffic aisles, promoting a new collection. | High visibility, holds more stock. | Takes up valuable floor space. |

| Slatwall/Pegboard | Organizing a variety of styles on a wall. | Space-efficient, very flexible. | Requires existing wall fixtures. |

Structural Integrity for Hats

Once you know the type, you need to think about structure. I once saw a display for baseball caps fail because the designer used single-wall cardboard for hooks that had to hold ten caps each. They sagged within a day. Hats, especially fitted caps or wide-brimmed hats, need proper support. Think about how many hats it will hold. Will customers be trying them on? The display must be stable enough to handle that interaction. We always build our custom display solutions with this kind of real-world use in mind.

Which materials and printing methods should you choose for your hat display?

Are you worried your cardboard display will look cheap or fall apart? The right material choice prevents this common problem. I will show you how to select materials that look premium and last.

For hat displays, B-flute or E-flute corrugated cardboard offers the best balance of strength and a smooth printing surface. Pair it with high-quality printing and a protective laminate (gloss or matte) to ensure a durable, professional finish that elevates your brand.

The material you choose is the foundation of your display. It affects the look, the feel, and the lifespan of your unit. In my early days, I learned a tough lesson by trying to save a client a few cents per unit with a cheaper paper stock. The displays looked dull and scuffed easily, which hurt the brand's premium image. Never compromise on the foundation. Let's look at the best options for making your hats look their best.

Cardboard Grades Explained

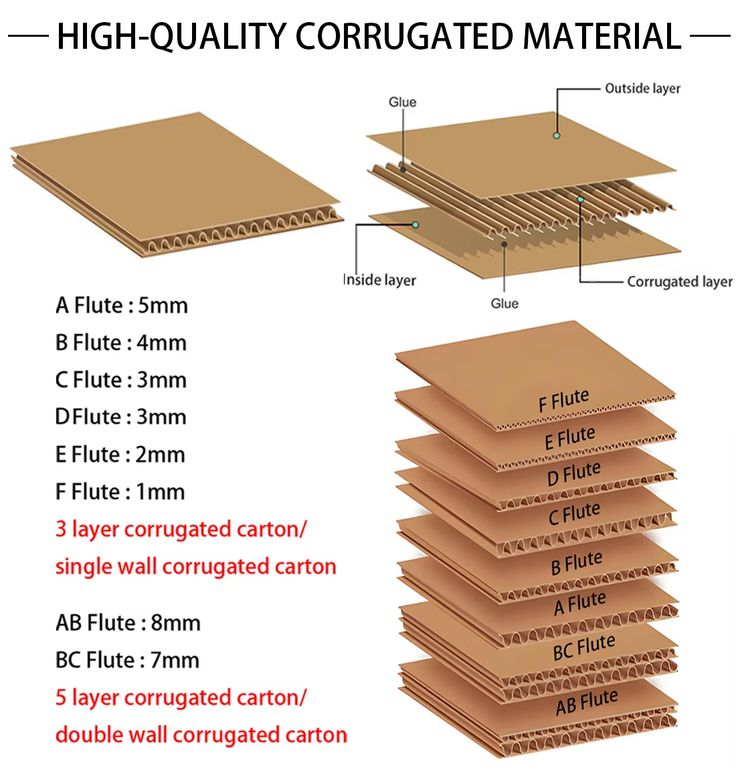

Not all cardboard is created equal. The "flute," which is the wavy layer between the liner boards, determines the thickness and strength. For a product designer, knowing which flute to specify is critical.

| Flute Type | Thickness (Approx.) | Characteristics | Best Use Case |

|---|---|---|---|

| E-Flute | ~1.5 mm | Thin, excellent print surface, good for folding. | Lightweight countertop displays, packaging. |

| B-Flute | ~3.0 mm | Good all-rounder, strong, good printability. | Most common for floor displays and shelves. |

| EB-Flute | ~4.5 mm | Very strong and durable, combines two flutes. | Heavy-duty displays, structural components. |

For most hat displays, B-flute is the sweet spot. It provides enough strength to hold the hats without being overly bulky. We also focus on eco-friendly solutions, using recycled and recyclable materials whenever possible.

Printing and Finishing Touches

Your graphics are what will stop a customer in their tracks. Digital printing is perfect for smaller quantities or prototypes because it has low setup costs. For large runs, offset printing gives you the best quality and color consistency. But do not stop there. A finish, or lamination, protects the print from scuffs and moisture. A gloss lamination makes colors pop, while a matte finish gives a more subtle, premium feel. This small detail can make a huge difference in how customers perceive your brand.

How do you turn your design into a real, manufacturable product?

Do you have a great design but are unsure how to produce it? The step from a digital file to a physical prototype can be tricky. Let's make that process simple and foolproof for you.

Turn your design into reality by first creating a dieline and a 3D mockup to test functionality. Next, produce a physical prototype to check fit and stability with actual hats. This iterative process ensures your final production run is flawless and meets all retail requirements.

This is where the magic happens. A designer like Peter can create a beautiful render, but if it cannot be built efficiently, it's just a picture. In my 16 years of experience, I have found that a solid prototyping process saves everyone time, money, and headaches down the road. It is about testing every assumption before you commit to producing hundreds or thousands of units. A little extra work upfront guarantees a smooth and successful production run.

The Prototyping Process Step-by-Step

We follow a strict process to ensure nothing is missed. It moves from the digital to the physical world, catching any potential issues along the way.

- Structural Design & Dieline: First, our engineers translate the concept into a structural file, often using CAD software. This file, called a dieline, is the flat blueprint for the display.

- 3D Mockup: We use this dieline to create a 3D digital mockup. This helps visualize the final product and is a great tool for getting client approval before we cut any material.

- The White Sample: Next, we produce an unprinted physical sample. This "white sample" allows us to test the structure, assembly, and fit with the actual hats. We check for stability and make sure it is easy for store staff to assemble.

- The Printed Sample: Once the structure is approved, we create a fully printed and finished sample. This is the final check to ensure colors are correct and the graphics align perfectly.

Preparing for Mass Production

After the final prototype is approved, we move to production. But a key consideration is shipping. We design most of our displays to ship flat-packed. This dramatically reduces shipping costs and storage space. However, this means you must include clear, easy-to-follow assembly instructions. I remember a client who launched a brilliant display but forgot instructions. The result was a mess of improperly assembled units in stores. We learned from that and now create simple, visual guides for every project. This final touch ensures your hard work in design is perfectly executed at the retail level.

Conclusion

A successful hat display blends smart design, the right materials, and a solid production process. By following these steps, you can create a powerful sales tool that showcases your products perfectly.