Juggling designers, printers, and shippers for your displays? This complex process often leads to delays and errors. Imagine a single partner handling everything seamlessly from start to finish.

A one-stop service for cardboard displays benefits brands by streamlining communication, reducing costs, and ensuring consistent quality. This integrated approach accelerates your time to market and simplifies project management, leading to a better final product with less hassle.

Over my 16 years in this industry, I've seen firsthand how fragmented supply chains can turn a great display idea into a logistical nightmare. It’s why we shifted our focus to being a complete solution for our clients. A designer would hand off a file, only to find the printer used the wrong stock or the fabricator made a structural mistake. The finger-pointing was endless. But when you partner with one company that handles everything, the entire dynamic changes. The focus shifts from avoiding blame to achieving a shared goal. Let's break down the specific advantages of this integrated approach.

How Does a Single Partner Simplify the Design-to-Production Workflow?

Frustrated by designs getting lost in translation between teams? Miscommunication can compromise your vision. A unified team ensures your original concept is perfectly executed without constant rework.

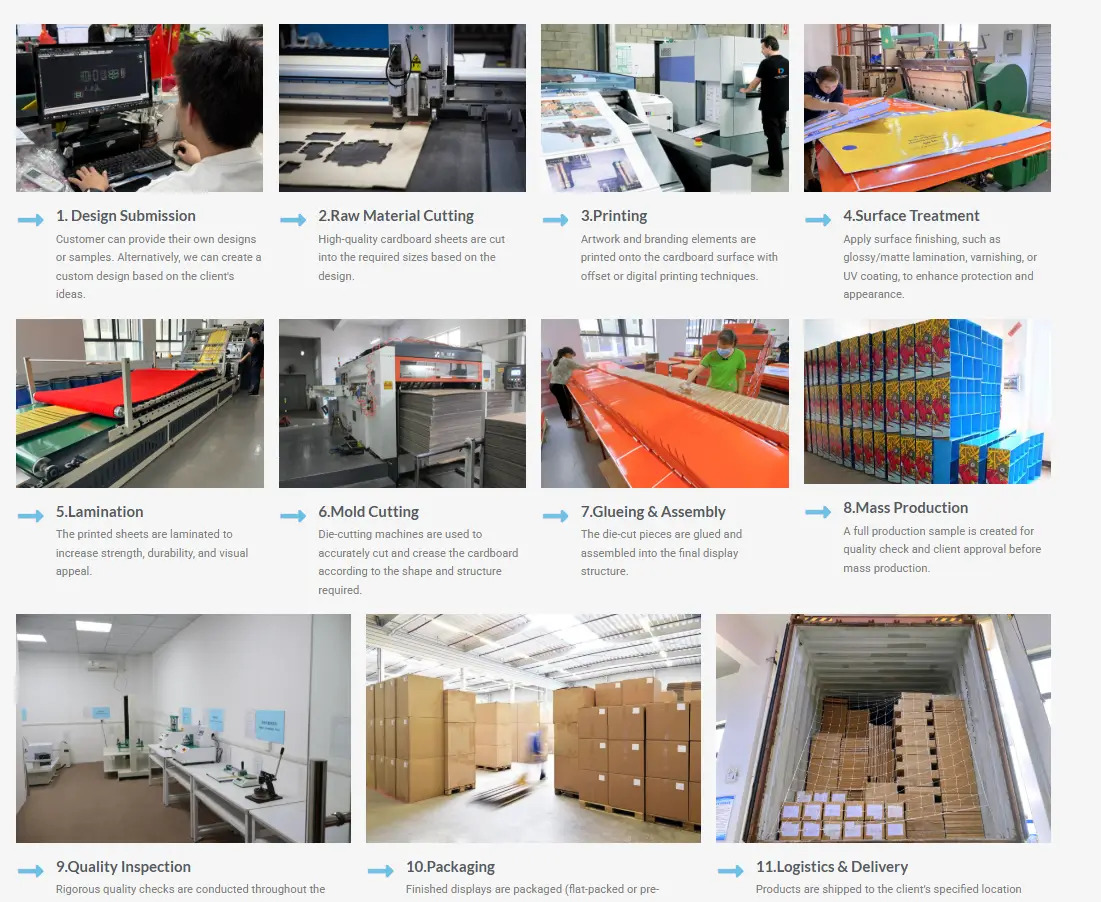

A single partner simplifies your workflow by creating one continuous communication channel. From the initial sketch to the final production run, one team manages the entire process. This eliminates handoff errors and ensures the design intent is maintained throughout, saving you time and stress.

When I talk to designers like Peter, they often tell me their biggest headache is the gap between their concept and the manufactured reality. A one-stop service closes that gap completely. Your project isn't just a file passed from one company to the next; it's a single, cohesive process managed under one roof. This creates a powerful feedback loop.

Cohesive Design and Engineering

Our designers and structural engineers work side-by-side. This means a designer's creative vision is immediately reviewed for structural soundness and manufacturing efficiency. I remember a project for a beverage company where the initial design looked amazing but would have been too weak to hold the product. Because our teams sit together, our engineer suggested a minor internal support change in minutes. It didn't alter the look but made the display rock-solid. This kind of instant collaboration is impossible when you're dealing with separate firms.

Unified Project Management

Here’s how the two workflows typically compare:

| Traditional Workflow (Multiple Vendors) | One-Stop Service Workflow (Single Partner) |

|---|---|

| Designer sends files to Vendor A (Printer). | Designer sends files to a single Project Manager. |

| Designer coordinates with Vendor B (Cutter). | Project Manager coordinates all internal teams. |

| Errors in communication between vendors. | All teams use the same project brief and files. |

| Delays in one stage impact the whole chain. | Seamless transitions between design, print, and cut. |

| Multiple points of contact and invoices. | One point of contact, one invoice. |

This simplified structure means you, the designer, can focus on design, not on playing telephone between three different suppliers. You get one dedicated contact who knows your project inside and out, from the first call to the final delivery.

Can a One-Stop Shop Really Reduce Your Overall Costs?

Worried about hidden costs from multiple vendors adding up? Coordinating different suppliers often brings unexpected expenses. Consolidating with one partner can offer significant, predictable savings for your project.

Yes, a one-stop shop reduces overall costs significantly. You benefit from bundled service pricing, lower administrative overhead, and optimized material usage. Early-stage design optimizations for manufacturing prevent expensive changes later, ensuring your budget stays on track from start to finish.

Everyone wants to save money, but it’s crucial to look at the total cost of a project, not just the price on an estimate. Working with multiple vendors might feel like you're getting competitive quotes at each stage, but the hidden costs and inefficiencies often wipe out those savings. I've seen it happen time and again. A one-stop provider creates value in several key areas that directly impact your bottom line.

Design for Manufacturability (DFM)

This is probably the biggest cost-saver. When your display is designed by the same people who will make it, it’s designed for their machines. We know the exact size of our cardboard sheets and the capabilities of our printers and cutters. We can adjust a design by a few millimeters to fit more units on a single sheet, drastically reducing material waste and cost. A freelance designer wouldn’t have this specific production knowledge. This optimization happens at the very beginning, preventing costly re-designs or wasteful production runs.

Economies of Scale and Bundling

The logic is simple. When you bundle services—design, printing, cutting, assembly, and even shipping—with one provider, you get a better price. We buy our materials in huge quantities, and we pass those savings on. It’s more efficient for us to manage a project from end to end, so we can offer a more competitive price than the combined total of three or four separate vendors. Plus, think of the administrative savings. Your accounting department processes one set of invoices from one partner, not four. That's a real saving in man-hours.

| Cost Area | Multiple Vendors | One-Stop Service |

|---|---|---|

| Material Waste | High (Design not optimized for manufacturer's specs) | Low (Design optimized for specific machinery) |

| Admin Fees | High (Multiple invoices, contracts, contacts) | Low (One point of contact, one invoice) |

| Rework Costs | Moderate (Errors due to miscommunication) | Minimal (Integrated team prevents errors) |

| Shipping | Complex (Coordinating factory to packager) | Streamlined (Handled by one logistics team) |

Ultimately, a one-stop partner gives you cost certainty. The price we quote is the price you pay because we control all the variables.

How Does Integrated Quality Control Improve the Final Product?

Have you ever received a final display where the colors were off or the structure was weak? Blame gets passed around. A single supplier means total accountability for quality.

Integrated quality control improves the final product by establishing a single standard of excellence from start to finish. The same team oversees material selection, printing accuracy, structural integrity, and final assembly. This eliminates finger-pointing and ensures a consistently high-quality display.

For a brand, consistency is everything. You need your brand's specific shade of red to be the same on every single display, in every single store. When you use different suppliers, achieving this consistency is a constant battle. The printer blames the paper supplier, who blames the designer's file. With a one-stop service, there is nowhere to hide. We are 100% accountable for the final product because we managed every step.

End-to-End Accountability

I once worked with a client who came to us after a disastrous campaign. Their previous supplier network produced displays where the main panel, printed by one company, was a different shade of blue than the side panels, printed by another. It looked unprofessional and damaged their brand image. At Lddisplay, we own the entire process. We calibrate our equipment to match the client's brand colors perfectly and use materials from the same batch for an entire job. Because we control everything, we guarantee consistency.

Structural Integrity and Material Checks

Quality isn't just about color. It’s also about durability. A display that collapses in a store is a failure. Our integrated process includes several quality checkpoints:

| Quality Control Point | What We Check | Why It Matters |

|---|---|---|

| Material Sourcing | Cardboard grade, flute type, and finish. | Ensures the display can hold the required weight. |

| Pre-press Check | Color profiles (CMYK/Pantone), resolution. | Guarantees print colors match the brand's guidelines. |

| First-Off-the-Line | A full assembly of the first unit produced. | Catches any cutting or creasing errors before mass production. |

| Mid-Production Spot Checks | Pulling units to check for print and structural consistency. | Maintains quality throughout the entire run. |

| Final Assembly | Verifying all parts fit together perfectly before packing. | Ensures easy setup and a professional look in-store. |

This rigorous, multi-stage quality control process is only possible when one team is responsible for the entire journey of the display. It transforms quality from a hope into a guarantee.

Conclusion

In short, a one-stop service streamlines your workflow, saves money, and guarantees better quality. It simplifies everything, letting you focus on creating great designs, not managing suppliers.