Struggling to pick the right display for your product? A wrong choice can waste your budget and hurt sales. Let me help you find the perfect cardboard display for your needs.

To choose the right cardboard display, you must consider your product's size and weight, your retail space, and your marketing goals. Select floor displays for high-traffic areas, counter displays for impulse buys, pallet displays for bulk products, and pegboards for hanging items. Each serves a unique purpose.

I've seen many clients struggle with this decision. The options can feel overwhelming. But understanding the basics makes it much easier. You just need to know what the displays are called, what they are made of, and how strong they are. Let's break it down together. This will help you feel confident in your next project.

What are cardboard displays called?

Are you confused by all the industry jargon? Using the wrong terms can lead to miscommunication with your suppliers. Learn the correct names to communicate clearly and get exactly what you need.

Cardboard displays are generally called Point of Purchase (POP) or Point of Sale (POS) displays. Specific types include floor displays, counter displays (or CDU for Counter Display Unit), pallet displays, and pegboard displays. Knowing these terms helps you specify your needs accurately with designers and manufacturers.

Knowing the right name for a display is the first step in any successful project. It ensures everyone is on the same page. When I first started lddisplay 16 years ago, a client kept asking for a "big box thingy for the aisle." It took a few calls and some sketches to figure out he wanted a pallet display. Clear terms save everyone time and prevent costly mistakes. For a skilled designer like Peter, using precise language builds trust with clients and makes the production process so much smoother. It helps him translate a vision into a reality without guesswork. It’s the foundation for a successful collaboration between the client, the designer, and the factory.

Common Industry Terms

Here’s a simple table to help you remember the most common names:

| Term | Full Name | Description |

|---|---|---|

| POP | Point of Purchase | Placed where customers make purchasing decisions, like in an aisle. |

| POS | Point of Sale | Located right at the checkout counter to encourage last-minute buys. |

| FSDU | Free Standing Display Unit | Another name for a floor display that stands on its own. |

| CDU | Counter Display Unit | A small display box designed for countertops or checkout areas. |

What's the strongest type of cardboard?

Do you worry that your display will collapse under the weight of your products? A weak display can lead to damaged goods, a messy retail floor, and a poor brand image.

The strongest type of cardboard for displays is typically triple-wall corrugated board. This material has three layers of fluting between four liner sheets. This structure gives it exceptional strength and rigidity. It is perfect for heavy items like beverages, canned goods, or bulk products on pallet displays.

The strength of corrugated board comes from its engineered structure, just like an arch in a bridge. The wavy layer, called the flute, creates air pockets that provide cushioning and rigidity. More walls mean more strength. But a strong material is useless if the display is poorly designed or difficult to assemble. A common complaint from retailers is that displays take too long to set up, costing them valuable staff time. This is a major challenge I've focused on solving. At lddisplay, we develop designs that are not just strong, but also incredibly easy to assemble. I'm proud that my team has created styles that are so simple, a store employee can assemble a full-sized floor display in just two seconds. This innovation saves our clients huge labor costs and ensures our strong designs are always set up correctly.

What are the three types of cardboard?

Are you feeling overwhelmed by all the material choices for your display? Choosing the wrong material can ruin your design's look, feel, and function, leading to a failed campaign.

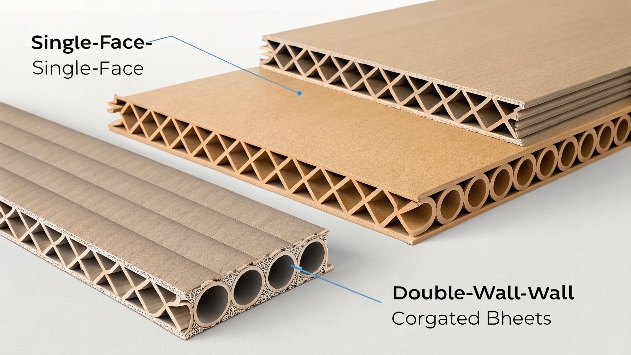

The three main types of cardboard used in displays are single-face, single-wall, and double-wall corrugated board. Single-face is just one liner sheet glued to one fluted sheet. Single-wall has a flute layer sandwiched between two liner sheets. Double-wall has two flute layers and three liners for added strength.

Choosing the right type of board is critical. I've seen designers try to use single-wall board for a project that clearly needed double-wall, just to save a little on the budget. The prototype always fails, and it ends up costing more to fix. My advice is to always test the material with the actual product weight. It saves a lot of headaches. The type of board also affects how your graphics look. A high-quality outer liner makes your brand colors pop. This is non-negotiable for a premium look. We use an advanced color management system at lddisplay to ensure the colors on the display perfectly match your brand's official colors. This gives customers the perfect visual experience and reinforces your brand identity at a glance.

A Closer Look at Cardboard Layers

| Type | Structure | Common Use Cases |

|---|---|---|

| Single-Face | One liner + one flute | Protective wrapping, inner packaging, light-duty padding. |

| Single-Wall | Liner + flute + liner | The most common type for shipping boxes and simple retail displays. |

| Double-Wall | Liner + flute + liner + flute + liner | Shipping heavy items, floor displays requiring more strength. |

Which type of cardboard is best for strength?

Do you need a display that can handle some serious weight? Your brand reputation is on the line. A failed display looks unprofessional and can be dangerous. Let's find out what works.

For maximum strength, double-wall or triple-wall corrugated board is the best choice. The right one for you depends on your product's weight. The flute profile, like B-flute or C-flute, also plays a critical role in providing crush resistance and stacking strength for your display.

True strength comes from combining the right material with smart structural design. It's not just about using the thickest board. You have to think like an engineer. But strength on the retail floor is only half the battle. The display must also survive shipping, especially for export orders. A display that arrives damaged is completely useless. This is a critical step many people overlook. At lddisplay, every international order goes through a strict safety protocol. We conduct waterproof tests on our packaging to protect against moisture. We also design special protective cardboard inserts to guard the corners and edges of displays shipped fully assembled. We decide on the best packaging method, whether that's flat-packed or pre-built and palletized, to guarantee safety and cost-effectiveness. This careful planning ensures every display we ship arrives in perfect condition, ready to do its job.

Conclusion

Choosing the right cardboard display means understanding types, materials, and strength. Think about your product and goals, then work with an experienced partner to bring your vision to life.