Struggling with logistical nightmares? Shipping heavy displays eats into your budget, and complex setups frustrate store staff. There is a much simpler way to get your products on the retail floor.

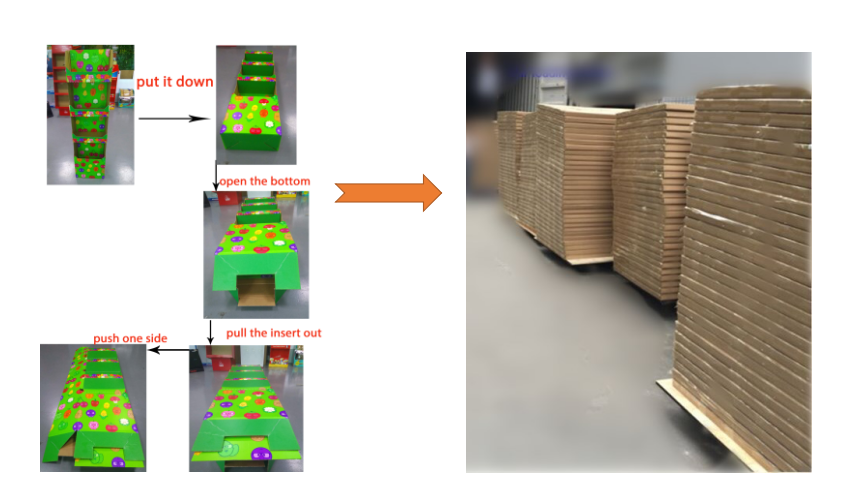

Cardboard displays simplify your supply chain because they are lightweight and can be shipped flat. This drastically cuts transportation costs and storage needs. Plus, they are typically easy to assemble in-store, saving on labor.

After 16 years in this business, I’ve seen it all. I’ve had clients come to me, tired of dealing with heavy, expensive display units that cause more problems than they solve. They wanted to know if there was a better way. I always tell them the same thing: the solution starts with reconsidering your materials. Let's look at how choosing cardboard can make a huge difference from the moment a display leaves the warehouse to the moment a customer sees it in the store.

Are High Shipping and Storage Costs Hurting Your Budget?

Your displays look great, but are they secretly draining your resources? The weight and bulk of traditional materials like wood or metal lead to high shipping fees and demand huge amounts of warehouse space.

You can solve this by switching to cardboard displays. Because they are lightweight and packed flat, they reduce shipping costs by up to 80%. Their compact, flat-packed nature also means you can store more units in less space, freeing up valuable warehouse real estate.

I remember a client, a snack food company, who was using permanent metal racks. Their shipping budget was out of control. When we sat down and looked at the numbers, it was a real eye-opener for them. The cost wasn't just in the shipping from our factory to their warehouse, but also in the distribution to hundreds of individual grocery stores. We designed a series of floor displays and counter displays using corrugated cardboard. The best part? We designed them to ship flat. The impact was immediate and massive. They could fit five times the number of displays on a single pallet. This single change completely transformed their logistics budget. As a designer like Peter, you can be the hero who brings these savings to the table. It's not just about aesthetics; it's about smart, cost-effective design.

The Financial Impact of Material Choice

| Feature | Traditional Displays (Wood/Metal) | Cardboard Displays |

|---|---|---|

| Material Weight | Heavy | Lightweight |

| Shipping Cost | High | Low |

| Storage Requirement | Bulky, requires large space | Flat-packed, minimal space |

| Assembly | Often requires tools and skilled labor | Simple, tool-free setup |

Thinking about these factors during the design phase is crucial. You can create a brilliant design, but if it's too expensive to ship or too difficult to store, it fails before it even gets a chance to shine.

How Can You Make In-Store Setup Faster and Easier?

Are retail staff struggling to assemble your displays? Complex instructions and multiple parts lead to wasted time, incorrect setups, and a messy store floor, which ultimately hurts your brand's presentation.

The answer is designing for simplicity. Cardboard displays can be engineered for intuitive, tool-free assembly that takes just minutes. We often create pre-packed displays, or PDQs, that arrive filled with product, ready to be placed directly on the shelf or floor.

As a designer, you hold the power to make life easier for everyone down the line. I always tell my team to think about the person who will be putting the display together. It's likely a busy retail employee who has a million other things to do. They don't have time for a complex instruction manual and a bag of screws. That's why we focus on interlocking tabs, simple folds, and clear, visual instructions printed right on the display if needed. I once worked with a cosmetics brand launching a new lipstick line. We designed a counter display that shipped flat but could be popped open and assembled in under 60 seconds. We even pre-packed the lipstick testers into the display. The feedback from the retail stores was phenomenal. They loved the efficiency and asked our client to use similar displays for all future promotions. This is where a designer like Peter can truly shine, by blending structural integrity with human-centered design that considers the end-user's experience.

Key Design Principles for Easy Assembly

- Minimize Parts: The fewer pieces, the better. Can a single die-cut piece be folded into the final shape?

- Use Intuitive Connections: Design with simple slots and tabs that lock together securely without needing glue or tools.

- Provide Simple Instructions: Use clear, graphic-based instructions. Better yet, make the assembly so obvious that instructions aren't even needed.

Can Your Displays Be Both Effective and Eco-Friendly?

You need displays that grab attention, but you're also facing pressure to be more sustainable. It feels like you have to choose between impactful marketing and environmental responsibility, a real challenge for any designer.

You don't have to compromise. Cardboard is the perfect solution. It's often made from a high percentage of recycled materials and is fully recyclable itself after use, simplifying the end-of-life logistics for retailers.

Sustainability is no longer a "nice-to-have"; it's a core business requirement. For a designer like Peter, this is a fantastic opportunity to lead. When I started lddisplay, eco-friendly options were a niche request. Now, it's part of nearly every conversation. I always guide my clients toward materials that are not just made from recycled content but are also easy to recycle. We can use vegetable-based inks and avoid plastic laminates to ensure the entire display can go into a single recycling stream. This simplifies the supply chain at the very end of its life. Instead of the retailer having to pay for disposal of a heavy, mixed-material unit, they can simply break down the cardboard display and toss it in their standard cardboard recycling bin. This saves them time and money on waste management. It's a win for our client's brand image, a win for the retailer, and a win for the planet.

Conclusion

By choosing cardboard, you simplify logistics, cut costs, and improve sustainability. It's a strategic decision that streamlines your entire supply chain from the warehouse to the retail floor.