Your new product display looks great in the design file, but will it succeed in-store? A bad provider can sink your launch with delays, damage, or poor quality, costing you sales.

A truly reliable retail display provider ensures success from start to finish. They deliver displays that are easy to assemble, feature perfect brand color matching, and are packaged securely to survive international shipping. This comprehensive approach guarantees your vision becomes a reality on the retail floor.

Finding a partner you can trust is everything in this business. Over my 16 years in the industry, I've seen how a project can go wrong when one piece of the puzzle is missing. A great design doesn't matter if it can't be assembled. Perfect colors are useless if the display arrives broken. True reliability is about mastering every single step. It’s about a commitment that goes beyond just manufacturing. Let me walk you through what you should look for to ensure your next display project is a success.

How do you determine if a display is effective?

Your display design is approved, but the real test is on the retail floor. If it's too complex or the colors are off, it fails, wasting your entire investment.

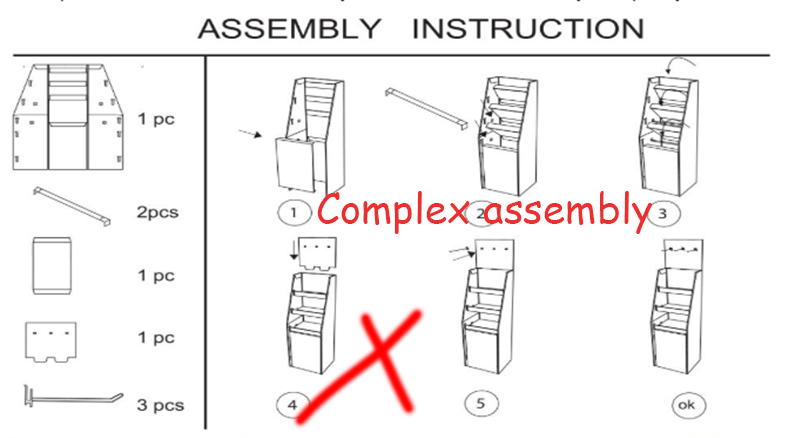

An effective display is one that is incredibly easy for store staff to assemble and perfectly matches your brand's colors. It should add value by saving labor costs1 and creating a seamless, professional visual experience2 that attracts customers and boosts sales, not create problems.

When a designer like Peter finalizes a display, his job is only half done. The concept must translate into a practical tool for the sales floor. If it doesn't, it’s not effective, no matter how beautiful it looks on a computer screen. From my experience, two of the biggest factors that often get overlooked are the assembly process3 and color accuracy4. These are the details that separate an average provider from a great one. A truly effective display has to work in the real world, and that means it has to be simple to build and visually perfect.

The Hidden Cost of Difficult Assembly

I once heard a story from a client about a previous project. Their displays arrived at a major retail chain, but the assembly instructions were a nightmare. Store staff spent an hour on each one, and many were built incorrectly or just left in the back room. It was a total disaster. The time and labor cost the retailer a fortune, and my client’s product never got the visibility it deserved. This is a common problem. That’s why at Lddisplay, we focus heavily on creating designs that are simple to assemble. We have developed structures that can be set up in minutes, and some of our pop-up displays can be ready in just two seconds. This isn't just about convenience; it's about respecting the client's investment5 and the retailer's time. An effective display removes friction from the sales process. Easy assembly means your product gets on the floor faster, looks the way it was designed to, and store employees are happy to work with it.

Why Perfect Color Matching is Non-Negotiable

Brand consistency is critical. Your customers recognize you by your colors. When the color on your display is even slightly off from your product packaging, it cheapens the entire presentation. It creates a subconscious disconnect for the shopper and can damage your brand's premium image. A reliable provider understands this and invests in advanced technology to prevent it. We use a sophisticated color management system to ensure that the final printed color on the cardboard perfectly matches the specific Pantone (PMS) colors of your brand. It’s a precise science. This guarantees that your brand identity remains strong and consistent across all marketing materials. Below is a simple breakdown of the difference this makes.

| Feature | Standard Printing | Advanced Color Management |

|---|---|---|

| Consistency | Colors can vary between print runs. | Colors are consistent every time. |

| Brand Match | "Close enough" is often the result. | An exact match to your brand's PMS color. |

| Visual Impact | Can look unprofessional or cheap. | Creates a premium, seamless brand look. |

| Process | Basic color calibration. | Spectrophotometer-based, data-driven. |

An effective display must be a perfect extension of your brand, and that starts with getting the color exactly right.

What is essential for successful merchandise display delivery?

You've designed a brilliant display. It's easy to build and the colors are perfect. But it all means nothing if it arrives at the destination damaged and unusable.

Essential for a successful delivery, especially for overseas orders, is a robust shipping strategy6. This includes smart packaging choices like palletizing7, performing waterproof tests8, and using custom-designed internal protection to ensure displays arrive in perfect condition, ready for the sales floor.

The journey from our factory to a retail store floors somewhere across the ocean is the final, critical step. Over the years, I've learned that you have to plan for the worst-case scenario during shipping. A container can be dropped, exposed to extreme humidity, or handled roughly by port workers. A reliable provider doesn't just hope for the best; we engineer a solution for a safe delivery. The security of the shipment is just as important as the design of the display itself. This focus on logistics is a key part of what makes a partnership successful. It’s our responsibility to make sure the hard work we all put into the design and production pays off when the box is opened.

The Importance of a Secure Shipping Foundation

How your displays are packed and loaded for transit makes a huge difference. There are two main methods: floor loading individual cartons or securing cartons onto pallets. While floor loading might seem cheaper initially, it’s a huge risk. Boxes can shift, get crushed under their own weight, and are handled multiple times, increasing the chance of damage. This is why we almost always recommend palletizing7. We stack the cartons neatly on a wooden pallet, then use corner protectors and wrap the entire unit tightly in protective film. The pallet is then moved as a single, stable unit by a forklift. It’s handled less, is far more stable, and is protected from impacts. It's a system designed for safety and efficiency, ensuring the displays inside are shielded from the chaos of global logistics.

| Shipping Method | Palletizing (Recommended) | Floor Loading (High Risk) |

|---|---|---|

| Handling | Moved once as a single unit with a forklift. | Individual boxes handled many times. |

| Stability | Very stable, cartons are secured together. | High risk of shifting and toppling. |

| Damage Risk | Low. The structure is strong and protected. | High. Cartons can be crushed or dropped. |

| Unloading | Fast and efficient. | Slow and labor-intensive. |

Proactive Protection Against the Elements

When displays are shipped by sea, they can spend weeks inside a metal container. The temperature changes can cause condensation, meaning your cardboard displays could arrive damp, warped, and moldy. A reliable supplier anticipates this. We conduct waterproof testing by wrapping our pallets in high-quality film. We ensure every seam is sealed to create a barrier against moisture. This simple step is a crucial part of our quality control9. Furthermore, we think about structural integrity10 from the inside out. We don't just put your flat-packed displays in a basic box. We design the shipping carton itself to be a protective shell. We often add custom-fit "protection cards" or honeycomb cardboard inserts that absorb shock and prevent the corners and edges of your displays from being crushed. This detailed approach is essential for a successful delivery and gives our clients peace of mind.

Conclusion

A reliable provider focuses on what matters: easy assembly, perfect color matching, and secure shipping. This ensures your vision is executed flawlessly from the factory to the retail floor.

-

Discover how well-designed displays can streamline operations and reduce labor costs for retailers. ↩

-

Explore the elements that contribute to a professional visual experience that attracts customers. ↩

-

Explore the critical factors in the assembly process that can make or break a retail display's effectiveness. ↩

-

Learn how color accuracy can enhance the visual appeal and professionalism of retail displays. ↩

-

Find out how a reliable provider can ensure that a client's investment is protected throughout the process. ↩

-

Learn about the essential components of a robust shipping strategy that ensures safe delivery. ↩

-

Discover how palletizing can enhance stability and reduce damage risk during shipping. ↩ ↩

-

Understand the significance of waterproof testing in ensuring the integrity of displays during shipping. ↩

-

Explore how quality control measures can ensure the reliability and effectiveness of retail displays. ↩

-

Learn about the importance of structural integrity in ensuring displays arrive undamaged. ↩