Struggling with flimsy displays and inconsistent branding? It's frustrating when your displays don't meet quality standards. You need a reliable manufacturing process that delivers every single time.

The best cardboard displays are made through a precise process. This includes structural design, high-fidelity printing with advanced color management, accurate die-cutting, and smart design for easy assembly. This ensures both strength and perfect brand representation, from the factory floor to the retail store.

When you invest in a custom cardboard display, you're not just buying a piece of cardboard. You are buying a key sales tool. The way it's made directly impacts your brand's image and your product's success. I’ve spent 16 years in this industry, and I've seen how small details in the manufacturing process can make or break a campaign. It's about combining strong materials, smart design, and beautiful printing into one effective package. Let's look at how we turn a simple sheet of paper into a powerful marketing asset that's both high-quality and efficient.

How are cardboard boxes manufactured?

Are your brand colors looking dull or wrong on your displays? This inconsistency can confuse customers and weaken your brand's impact, making your products look less professional.

Using an advanced color management system is key. We match your exact brand Pantone colors. This ensures that every display print is vibrant, accurate, and consistent, creating a perfect visual effect that strengthens your brand identity and attracts customers.

In my experience, color is one of the first things a customer notices. If the color is off, it sends a bad signal. That's why we take color management so seriously. The process starts with your design file. We don't just hit "print." We use a system that calibrates our printers to match specific Pantone color codes. This is a crucial step for quality.

Here's how it generally works:

- Pre-press Check: We analyze your brand's specific colors (like a unique blue or red).

- Digital Proofing: We create a digital proof to show you how the color will look. Sometimes we even mail a physical printed sample.

- Plate Making & Printing: For large runs, we use offset printing, which gives the best color quality. Our machines are regularly calibrated to ensure the color stays true from the first print to the last.

- Finishing: We might add a gloss or matte laminate. This not only protects the print but can also make the colors pop even more.

This focus on color ensures your display looks professional and aligns perfectly with all your other marketing materials.

How does the structure of corrugated cardboard make it suitable for packaging?

Worried your displays will bend or collapse under the weight of your products? A weak display not only looks bad but can also lead to damaged goods and lost sales.

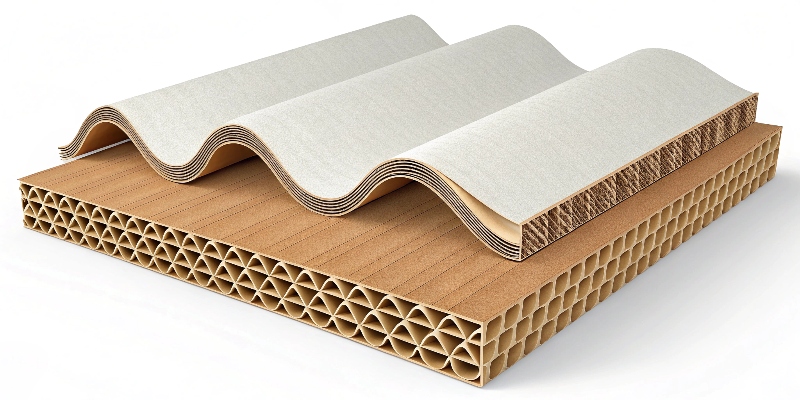

The secret is the corrugated structure. A wavy sheet of paper (the "flute") is glued between two flat linerboards. This design creates a surprisingly strong, rigid, and lightweight material, perfect for holding products securely.

I always tell my clients that not all cardboard is created equal. The strength comes from that simple "wave" inside. This structure provides amazing support without being heavy or expensive. Think about an arch in a bridge; the corrugated flute works in a similar way, distributing weight across the display. The real skill is in choosing the right type of corrugated board for the job. We have to consider how much weight the display needs to hold and for how long. We often choose between different flute types based on the specific needs of the product.

Here is a simple table to explain the common types:

| Flute Type | Thickness (Approx.) | Characteristics & Common Uses |

|---|---|---|

| B-Flute | 3 mm | Good printing surface, strong. Great for POP displays, retail packaging, and complex die-cuts. |

| C-Flute | 4 mm | The most common type. Good all-around cushioning and stacking strength. Used for shipping boxes. |

| E-Flute | 1.5 mm | Very thin with an excellent printing surface. Often used for small retail boxes and packaging. |

| BC-Flute | 7 mm | A double-wall combination. Very strong and durable. Used for heavy items or pallet displays. |

Choosing the right structure is the first step to building a quality display that performs well in a busy retail setting.

What is the process of manufacturing corrugated boxes?

Tired of displays that are a nightmare to assemble? Wasting store staff's valuable time on complicated instructions and parts is inefficient and costly for your retail partners.

We solve this by designing for simplicity. Many of our modern display stands are engineered for easy, intuitive assembly. Some can even be fully set up in just two seconds, saving huge amounts of labor costs and getting your product on the floor faster.

One of the biggest complaints I used to hear from clients was about assembly. They would ship a beautiful display to a store, only to have it assembled incorrectly, or not at all, because it was too hard. This is a huge waste. Manufacturing isn't just about making the parts; it's about thinking how the end-user will put them together. Quality and efficiency must include the final assembly step.

That’s why my team and I at Lddisplay started to focus on "user-friendly" engineering. We developed pop-up designs with built-in locking tabs that click into place. No tools, no confusing manuals, and no small parts to lose. For one client, we designed a floor display that a single person could take out of the box and have ready for products in literally two seconds. This innovation completely changed their in-store execution and saved them thousands in labor costs across hundreds of stores.

Are cardboard boxes eco-friendly?

Are you concerned about your products arriving damaged? A damaged shipment is a total loss. It means remaking the order, extra shipping costs, and a delayed launch, which is wasteful and hurts your bottom line.

A key part of our process is ensuring safe transport. We focus on smart packaging, like using pallets correctly and designing protective shipping cartons. We even waterproof test our packaging to make sure your displays arrive in perfect condition.

While cardboard itself is very eco-friendly because it's recyclable and biodegradable, true sustainability also means avoiding waste. A damaged product is the biggest waste of all. Over my 16 years, I've learned that a successful order is only complete when it's delivered safely. This is a critical part of the manufacturing process for any export business.

We have a three-step process to guarantee shipping safety:

- Smart Packing: We decide if your order needs to be on a pallet or not. Pallets add protection and make handling easier, preventing bumps and drops. We also wrap the entire pallet in plastic film to hold everything tightly.

- Waterproofing: Before final shipment, we put all cartons through a water-spray test. This simulates rain or humid conditions to ensure the outer box protects the displays inside from moisture.

- Structural Protection: For flat-packed displays, we design the outer shipping carton with reinforced corners and extra padding. For pre-assembled displays, we create internal cardboard structures to hold the display securely in place so it can't move or collapse during transit.

Conclusion

In short, manufacturing quality cardboard displays means focusing on great design, precise color, the right materials, easy assembly, and safe shipping. These steps ensure your success.