Stores are crowded and your product can easily get lost. What if your display could grab every shopper's attention and boost sales instantly?

To make your cardboard display stand out, focus on a unique structural design that is easy to assemble. Then, use vibrant, accurate colors that match your brand. Finally, add innovative features that engage customers and highlight your product's value. This combination creates an unmissable experience.

Getting your display to stand out is one thing. But making it practical, strong, and beautiful is the real challenge for designers and brand managers. It requires more than just a pretty picture; it needs smart engineering1 from start to finish. Let's break down how we achieve this for our clients.

How do you make a cardboard display stand?

Creating a display stand can seem complex. You might worry about the design, materials, and difficult assembly. I can show you a simple process that results in a professional and effective stand.

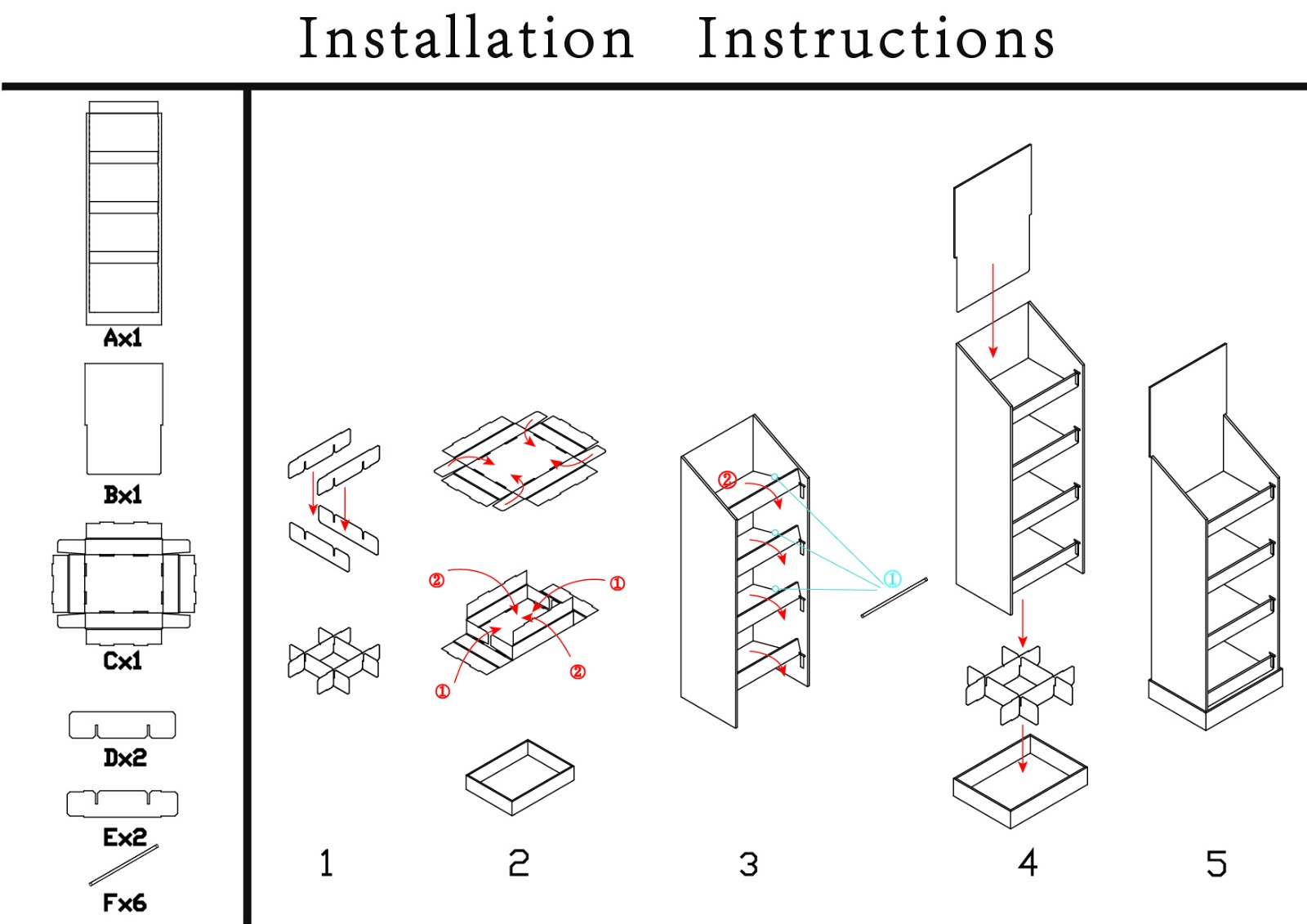

Making a cardboard display involves three main steps: design, printing, and assembly. The design phase creates the structure and graphics. Printing brings the visuals to life. A clever structural design ensures it can be assembled quickly and easily in the store, saving time and money.

The biggest headache for many brands is what happens in the store. A brilliant design is useless if the store staff can't build it. I remember getting calls from frustrated clients whose teams were spending hours trying to figure out complex displays. It was a clear sign we needed to innovate. The problem was that traditional displays often came with confusing instructions and many small parts. This wasted valuable time and money on labor costs.

So, we focused on creating simple, intuitive assembly methods. Our goal was to make it so easy that anyone could do it without instructions. We developed pop-up designs with automatic locking systems. One of our proudest innovations is a display that can be fully assembled in just two seconds. This completely changes the game for in-store execution. It removes stress, cuts labor costs, and makes sure the display looks perfect every time.

Here's how our new approach compares to the old way:

| Feature | Traditional Display | Lddisplay Easy-Assemble |

|---|---|---|

| Assembly Time | 20-40 minutes | Under 5 minutes |

| Tools Needed | Often requires tools | No tools needed |

| Labor Cost | High | Minimal |

| Setup Errors | Common | Rare |

For designers like Peter, this means they can create complex and eye-catching shapes without worrying about the practical frustrations of assembly.

How can you make cardboard look better?

Plain cardboard can sometimes look cheap. This can hurt your brand's premium image. But you can transform this simple material into a high-end display that attracts customers.

To make cardboard look better, you need high-quality printing and finishing. Use an advanced color management system to match your brand colors perfectly. Then, add finishes like gloss or matte lamination to enhance the look and feel, giving your display a professional appearance.

Color is everything for a brand. Early in my career, a major client was very unhappy because the red on their display did not exactly match the red on their packaging. The colors were close, but not perfect. It made their product look inconsistent. That experience taught me a valuable lesson: "close enough" is never good enough when it comes to brand identity. The color must be perfect.

To solve this, we invested in a very advanced color management system2. We don't just guess colors. We use special tools to measure color data and ensure our printers are perfectly calibrated. For every project, we can precisely match specific Pantone or CMYK values. This guarantees that the final display's color is an exact match to the client's brand guide. This process gives our clients total confidence. They know the design they approve on screen will look exactly the same in the store. Also, we add finishes like lamination. A gloss finish makes colors look more vibrant and pop. A matte finish gives a more subtle, premium feel. These small details make a huge difference in how customers see a brand.

How can you make a display stand out?

Your display is in a busy store, surrounded by competitors. How do you stop shoppers in their tracks? I’ll share some proven methods to make your display completely unmissable.

To make a display stand out, use a unique shape, bold graphics, and interactive elements. A surprising structure captures attention. Clear, strong messaging tells your story quickly. Adding a QR code or a small screen can turn passive viewers into engaged shoppers.

Making a display truly stand out requires thinking beyond a simple box with shelves. It's about creating an experience. We focus on three areas to achieve this: structure, graphics, and interactivity. For structure, we design shapes that are unexpected. Imagine a display shaped like a giant version of the product it holds. This instantly tells shoppers what you're selling from across the aisle.

For graphics, less is more. We use our advanced color control to create high-contrast, bold designs that are easy to see. The message must be simple and direct. A customer should understand the main benefit of your product in under three seconds. We avoid cluttering the display with too much text or too many images.

Finally, interactivity is a powerful tool. We can embed small digital screens to play short videos. We also use QR codes that shoppers can scan to get a discount or learn more. One of our most effective strategies is designing displays that ship pre-assembled in 3D. They arrive at the store protected by custom supports and are ready to go on the floor immediately. This "instant display" creates a huge impact and makes a brand look very professional and prepared.

How do you make cardboard strong enough to stand on?

You might worry that your cardboard display could collapse. What if it gets bumped by a shopping cart or loaded with heavy products? I’ll show you how we engineer cardboard to be incredibly strong.

To make cardboard incredibly strong, you must use the right material and smart structural engineering. We select multi-layered, high-density corrugated board. Then, we design internal supports and locking systems to create a display that can hold heavy weight and withstand store traffic.

A display failure is a brand's worst nightmare. It's costly and damages your reputation. Strength and durability are not optional. It all starts with the right material. We don't use just any cardboard. We carefully select the right type of corrugated flute and paper weight based on the products it will hold. I think of it like an architect designing a building; the foundation has to be perfect. We often use double-wall or even triple-wall board for heavy-duty displays.

But material is only half the story. The real secret is in the structural design. We create internal lattices and support walls that distribute weight evenly. This prevents any single point from taking too much stress. This engineering is also critical for surviving shipment, especially for international orders. A strong display is more likely to arrive in perfect condition. We run tests to make sure. We perform waterproof tests3 where we spray packaged displays with water to simulate rain during transit. This simple step has saved our clients from disastrous, water-damaged deliveries.

| Shipping Method | Protection Level | Best For |

|---|---|---|

| Flat-pack, No Pallet | Low | Small, domestic orders |

| Flat-pack, on Pallet | High | Large international orders |

| 3D Assembled, Boxed | Very High | Premium, ready-to-use displays |

For our pre-assembled 3D displays, we design custom protective cards4 that fit inside. These cards brace the structure during shipping, so it arrives without a single dent.

Conclusion

A standout display is a mix of smart design, perfect color, and strong engineering5. Get these key things right, and your product will capture attention and sell more.

-

Understand how engineering principles can improve the functionality of your displays. ↩

-

Explore the technology behind perfect color matching for brand consistency. ↩

-

Learn how testing can ensure your displays withstand various conditions during transit. ↩

-

Explore how protective designs can safeguard your displays during shipping. ↩

-

Understand how robust engineering can enhance the longevity and reliability of displays. ↩